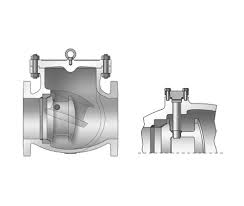

Tilting Disc Check Valve

The Application of Tilting Disc Check Valve

Cameron, a leading manufacturer of industrial valves, offers a range of innovative solutions, including the Chapman Tilting Disc Check Valve. These tilting disc check valves are designed to provide reliable one-way flow control in a variety of applications, such as HVAC systems, power plants, and industrial process equipment. The unique tilting disc mechanism allows for smooth, unobstructed flow in the forward direction while effectively sealing against backflow, ensuring the safety and efficiency of the fluid system. With their durable construction and customizable options, Cameron’s Tilting Disc Check Valves are a trusted choice for applications requiring dependable flow control.

What Are The Types Of Tilting Disc Check Valve?

Cameron’s Tilting Disc Check Valves come in a variety of types to meet the diverse needs of different applications:

Swing-Type Tilting Disc Check Valve:

This design features a hinged disc that swings open to allow forward flow and closes to prevent backflow. The swing-type valve offers a compact and simple construction.

Lift-Type Tilting Disc Check Valve:

In this configuration, the disc tilts and lifts off the valve seat to enable forward flow, providing a more streamlined flow path compared to the swing-type.

Dual Plate Tilting Disc Check Valve:

This valve utilizes two opposing tilting discs that open and close in a synchronized manner, offering enhanced reliability and flow control capabilities.

Silent Tilting Disc Check Valve:

The silent check valve design incorporates a cushioning mechanism to minimize the noise and water hammer effects associated with rapid valve closure, making it suitable for noise-sensitive environments.

What Is Tilting Disc Check Valve?

A Tilting Disc Check Valve is a specialized type of check valve that utilizes a tilting disc mechanism to control the flow of fluids in a one-way direction. Unlike traditional swing check valves, the disc in a tilting disc check valve is designed to tilt and lift off the valve seat, allowing fluid to flow freely in the forward direction while effectively sealing against backflow. This unique design feature enhances the flow efficiency and reduces the pressure drop across the valve, making it a popular choice for applications that require reliable and energy-efficient flow control, such as HVAC systems, industrial processes, and power generation equipment. Cameron, a renowned manufacturer of industrial valves, offers a range of tilting disc check valve solutions to meet the diverse needs of various industries.

How to Select the Right Tilting Disc Check Valve?

Flow Capacity: Determine the required flow rate and pressure drop characteristics to ensure the valve can handle the system’s flow demands.

Valve Size: Choose the correct valve size based on the pipe diameter and flow requirements to optimize performance and minimize pressure losses.

Material Compatibility: Assess the compatibility of the valve materials with the fluids, temperatures, and corrosive environments in the application.

Installation Requirements: Consider the available space, orientation, and accessibility to ensure the tilting disc check valve can be easily installed and maintained.

Noise and Water Hammer: If the application is sensitive to noise or water hammer, opt for a silent tilting disc check valve design with a cushioning mechanism.

By carefully evaluating these factors, users can select the Cameron Tilting Disc Check Valve that best suits their specific application needs, ensuring reliable and efficient flow control.

Features of Tilting Disc Check Valve

Smooth Flow

The tilting disc design offers a streamlined flow path, minimizing turbulence and pressure drop to enhance overall system efficiency.

Reliable One-Way Flow Control

The tilting disc mechanism effectively seals against backflow, ensuring unidirectional fluid control and preventing reverse flow.

Compact and Lightweight

The axial flow configuration of tilting disc check valves allows for a compact and lightweight valve design, making it suitable for space-constrained installations.

Customizable Options

Cameron offers a range of tilting disc check valve types (swing, lift, dual plate, silent) and material choices to accommodate diverse application requirements.

Reduced Noise and Water Hammer

The silent check valve design incorporates a cushioning mechanism to minimize noise and water hammer effects, making it suitable for noise-sensitive environments.

Easy Installation and Maintenance

The axial flow layout and compact size of tilting disc check valves simplify the installation process and facilitate routine maintenance.

Advantages and Disadvantages of Tilting Disc Check Valve

Advantages of Tilting Disc Check Valve:

High Flow Efficiency: The tilting disc design minimizes flow resistance, resulting in lower pressure drop and improved energy efficiency.

Reliable Backflow Prevention: The tilting disc mechanism provides a tight seal against reverse flow, ensuring effective one-way flow control.

Compact and Lightweight: The axial flow configuration allows for a compact and lightweight valve design, making it suitable for space-constrained installations.

Customizable Options: Manufacturers like Cameron offer a variety of tilting disc check valve types and material choices to meet diverse application requirements.

Reduced Noise and Water Hammer: The silent check valve design incorporates a cushioning mechanism to minimize noise and water hammer effects.

Easy Installation and Maintenance: The axial flow layout and compact size simplify the installation process and facilitate routine maintenance.

Disadvantages of Tilting Disc Check Valve:

Limited Flow Capacity: Depending on the valve size, tilting disc check valves may have a limited maximum flow capacity compared to larger check valve designs.

Potential for Disc Sticking: In applications with high suspended solids or viscous fluids, the tilting disc mechanism may be susceptible to sticking or binding, reducing the valve’s reliability.

Higher Cost: Tilting disc check valves can be more expensive than simpler check valve designs due to their more complex mechanisms and customization options.

The Specifications of Tilting Disc Check Valve

| Specification | Details |

|---|---|

| Type | Lift-Type Tilting Disc Check Valve |

| Ball Material | 316 Stainless Steel |

| Attachment Type | Flanged |

| Thread Standard | ANSI B16.5 |

| Thread Size | 4 inch |

| Body Material | Carbon Steel |

| Safe for Use With | Water, Steam, Oil, Air, Gas |

| Handle Type | Lever |

| Handle Material | Carbon Steel |

| Maximum Working Pressure (psi) | 285 psi |

| Maximum Working Pressure (bar) | 19.7 bar |

| Operating Pressure | 10-200 psi |