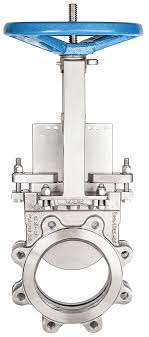

Kgc-Bd Knife Gate Valve

The Application of Kgc-Bd Knife Gate Valve

Introducing the Flowserve KGC-BD Knife Gate Valve, an exemplary choice from renowned knife gate valve manufacturers. The KGC-BD stands out for its superior performance in various applications. Unlike traditional gate valves, knife valve vs gate valve comparisons reveal its unique design, optimized for demanding conditions where reliable shut-off is crucial. With a design akin to the esteemed Dezurik knife gate valve, the KGC-BD offers exceptional sealing against slurries, powders, and other challenging media. Its robust construction and precise control make it ideal for industries such as mining, wastewater treatment, and pulp and paper. Experience reliable flow control and uncompromising performance with the Flowserve KGC-BD Knife Gate Valve.

What Is Kgc-Bd Knife Gate Valve?

The KGC-BD Knife Gate Valve is a specialized valve designed for reliable shut-off in demanding applications. It features a unique knife gate design, ensuring tight sealing against slurries, powders, and other challenging media. With its robust construction and precise control, it finds extensive use in industries such as mining, wastewater treatment, and pulp and paper.

How Does Kgc-Bd Knife Gate Valve work?

The KGC-BD Knife Gate Valve operates by using a sharp-edged blade, resembling a knife, to cut through and control the flow of media. When the valve is open, the knife gate is positioned parallel to the flow direction, allowing fluid to pass through. Closing the valve positions the knife gate perpendicular to the flow, effectively blocking it. This design provides reliable shut-off and is particularly effective for handling thick fluids, slurries, and solids.

Features of Kgc-Bd Knife Gate Valve

- Robust Construction: The KGC-BD Knife Gate Valve is built with sturdy materials, ensuring durability and reliability even in harsh environments.

- Knife Gate Design: Its unique knife gate design provides a tight seal against various media, including thick fluids, slurries, and solids.

- Bi-Directional Flow: Capable of controlling flow in both directions, enhancing versatility and applicability in different systems.

- Low Maintenance: Requires minimal maintenance due to its simple yet efficient design, reducing downtime and operational costs.

- Various Sizes: Available in a range of sizes to accommodate different flow rates and installation requirements.

- Corrosion Resistance: Constructed from materials such as stainless steel or corrosion-resistant alloys, making it suitable for corrosive environments.

- Easy Installation: Designed for easy installation and integration into existing systems, minimizing setup time and labor costs.

- Precise Control: Offers precise flow control, allowing for accurate regulation of fluid flow rates.

- Wide Range of Applications: Suitable for use in industries such as mining, wastewater treatment, pulp and paper, and more, due to its versatility and reliability.

Advantages of Kgc-Bd Knife Gate Valve

- Efficient Shut-Off: The KGC-BD Knife Gate Valve ensures efficient shut-off, preventing leakage and ensuring system integrity.

- Versatile Application: Suitable for a wide range of applications including mining, wastewater treatment, pulp and paper, and more.

- Robust Construction: Built with sturdy materials, it offers durability and reliability even in harsh operating conditions.

- Bi-Directional Flow Control: Capable of controlling flow in both directions, enhancing flexibility in system design.

- Low Maintenance: Requires minimal maintenance, reducing downtime and operational costs.

- Precise Flow Control: Offers precise control over fluid flow rates, allowing for accurate regulation.

- Corrosion Resistance: Constructed from corrosion-resistant materials, making it suitable for use in corrosive environments.

- Easy Installation: Designed for easy installation and integration into existing systems, minimizing setup time and labor costs.

- Cost-Effective: Provides cost-effective flow control solutions due to its efficiency, reliability, and low maintenance requirements.

The Specifications of Kgc-Bd Knife Gate Valve

| Specification | Details |

|---|---|

| Type | Knife Gate Valve |

| Ball Material | Stainless Steel or other corrosion-resistant alloy |

| Attachment Type | Lug, Wafer, Flanged |

| Thread Standard | ANSI B16.5, MSS-SP-81, EN 1092-1 |

| Thread Size | 2″, 3″, 4″, 6″, 8″, 10″, 12″, 14″, 16″, 18″, 20″, 24″ |

| Body Material | Cast Iron, Carbon Steel, Stainless Steel |

| Safe for Use With | Water, Sewage, Slurry, Pulp, Chemicals, Abrasive Media |

| Handle Type | Manual Handwheel, Gear Operator, Pneumatic or Hydraulic Actuator |

| Handle Material | Stainless Steel, Cast Iron, Aluminum |

| Maximum Working Pressure (psi) | Up to 150 psi (depending on size and material) |

| Maximum Working Pressure (bar) | Up to 10 bar (depending on size and material) |

| Operating Pressure | Varies depending on specific model and size, refer to manufacturer’s specifications |

The Parameter of Kgc-Bd Knife Gate Valve

- Type: Knife Gate Valve

- Ball Material: Stainless Steel or other corrosion-resistant alloy

- Attachment Type: Available in Lug, Wafer, or Flanged configurations

- Thread Standard: Conforms to ANSI B16.5, MSS-SP-81, EN 1092-1 standards

- Thread Size: Ranges from 2″ to 24″ for various flow rates and applications

- Body Material: Options include Cast Iron, Carbon Steel, or Stainless Steel

- Safe for Use With: Suitable for handling water, sewage, slurry, pulp, chemicals, and abrasive media

- Handle Type: Manual Handwheel, Gear Operator, or compatible with Pneumatic/Hydraulic Actuators

- Handle Material: Available in Stainless Steel, Cast Iron, or Aluminum

- Maximum Working Pressure (psi): Up to 150 psi (depending on size and material)

- Maximum Working Pressure (bar): Up to 10 bar (depending on size and material)

- Operating Pressure: Operating pressure varies depending on specific model and size, refer to manufacturer’s specifications for precise details

The Operation Theory of Kgc-Bd Knife Gate Valve

- Knife Gate Mechanism: Unlike traditional gate valves, such as the Clarkson knife gate valve, the KGC-BD employs a sharp-edged gate to regulate fluid flow.

- Directional Control: When open, the gate is positioned parallel to the flow direction, allowing fluid passage. Closing the valve shifts the gate perpendicular to the flow, effectively halting fluid movement.

- Sealing Functionality: The gate’s sharp edge slices through the media, ensuring a tight seal and minimal leakage.

- Versatility: Suitable for diverse applications, the KGC-BD excels in managing abrasive media, slurries, and solids, outperforming conventional gate valves.

- Gate Valve vs Knife Valve: While gate valves control flow through a linear motion of a gate, knife gate valves employ a gate with a sharpened edge to slice through the media. This design makes knife gate valves like the KGC-BD better suited for challenging environments with thick or abrasive fluids.

The Parameters Table of Kgc-Bd Knife Gate Valve

| Parameter | Details |

|---|---|

| Type | Knife Gate Valve |

| Gate Material | Stainless Steel, Cast Iron, or other corrosion-resistant alloy |

| Body Material | Cast Iron, Carbon Steel, Stainless Steel |

| Seat Material | EPDM, Natural Rubber, Nitrile, Metal (Stainless Steel) |

| Connection Type | Lug, Wafer, Flanged |

| Size Range | 2″, 3″, 4″, 6″, 8″, 10″, 12″, 14″, 16″, 18″, 20″, 24″ |

| Safe for Use With | Water, Sewage, Slurry, Pulp, Chemicals, Abrasive Media |

| Actuator Type | Manual Handwheel, Gear Operator, Pneumatic or Hydraulic Actuator |

| Actuator Material | Stainless Steel, Cast Iron, Aluminum |

| Maximum Working Pressure (psi) | Up to 150 psi (depending on size and material) |

| Maximum Working Pressure (bar) | Up to 10 bar (depending on size and material) |

| Operating Temperature | Up to 180°C (356°F) |