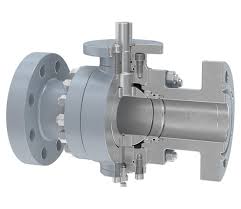

Grove Ball Valve

The Application of Grove Ball Valve

Flowserve Grove Ball Valve, including models such as Cameron Grove Ball Valve, Grove B4 Ball Valve, Grove B4C Ball Valve, and Grove B5 Ball Valve, offers exceptional reliability and performance in various applications. Renowned for their robust construction and precise engineering, Grove Ball Valves are widely utilized in industries requiring high-quality valves for fluid control. With a reputation for durability and longevity, Flowserve Grove Ball Valves ensure efficient operation and minimal downtime, making them ideal for critical processes in oil and gas, petrochemical, power generation, and other industrial sectors. Designed to withstand harsh operating conditions, these valves provide reliable shut-off and control, contributing to enhanced safety and operational efficiency across diverse applications.

grove ball valves

cameron grove ball valve

What Is Grove Ball Valve?

Grove Ball Valve, produced by Flowserve, is a robust and reliable valve renowned for its exceptional performance in various industrial applications. With precise engineering and durable construction, Grove Ball Valve ensures efficient fluid control and contributes to enhanced safety and operational efficiency.

How Does Grove Ball Valve work?

A Grove ball valve operates by using a rotating sphere with a hole in it to control the flow of fluid. When the valve is open, the ball is turned parallel to the direction of flow, allowing fluid to pass through. Closing the valve rotates the ball perpendicular to the flow, blocking it. This design offers reliable sealing and precise flow control, making it widely used in various industries.

Features of Grove Ball Valve

- Robust Construction: Grove ball valves are engineered with durable materials such as stainless steel or cast iron, ensuring longevity and resistance to corrosion.

- Bidirectional Flow: These valves can control the flow of fluid in both directions, enhancing their versatility and applicability in various systems.

- Bubble-tight Seal: The ball design provides a tight seal against leakage, even under high-pressure conditions, ensuring efficient and safe operation.

- Low Torque Operation: With their streamlined design and precision engineering, Grove ball valves require minimal torque to open and close, reducing the need for extensive manual effort.

- Versatile Applications: These valves find application in a wide range of industries, including oil and gas, chemical processing, water treatment, and HVAC systems, due to their reliability and adaptability to diverse operating environments.

- Easy Maintenance: Their simple design facilitates easy disassembly and maintenance, minimizing downtime and ensuring consistent performance over time.

- Various Sizes and Configurations: Available in a range of sizes and configurations, Grove ball valves can accommodate different flow rates and installation requirements, providing flexibility in system design.

Advantages of Grove Ball Valve

- Excellent Sealing: The design of Grove ball valves ensures tight sealing, preventing leakage even under high-pressure conditions, thus enhancing safety and efficiency.

- Smooth Flow Control: These valves offer precise flow control due to their spherical ball design, allowing for smooth regulation of fluid flow rates.

- Durability: Grove ball valves are constructed from robust materials, such as stainless steel or cast iron, ensuring longevity and resistance to corrosion, which reduces maintenance needs and enhances reliability.

- Bidirectional Operation: They can control flow in both directions, providing versatility in various applications and systems.

- Low Operating Torque: Grove ball valves require minimal torque to operate, reducing the need for extensive manual effort and making them easier to use.

- Wide Range of Applications: Due to their reliability and adaptability, Grove ball valves are suitable for use in diverse industries such as oil and gas, chemical processing, water treatment, and HVAC systems.

- Easy Installation and Maintenance: Their simple design facilitates easy installation and maintenance, minimizing downtime and ensuring consistent performance over time.

The Specifications of Grove Ball Valve

| Specification | Details |

|---|---|

| Type | Ball Valve |

| Ball Material | Stainless Steel or Brass |

| Attachment Type | Threaded or Flanged |

| Thread Standard | ANSI B1.20.1 or BSPP |

| Thread Size | 1/2″, 3/4″, 1″, 1-1/4″, 1-1/2″, 2″, 2-1/2″, 3″, 4″ |

| Body Material | Cast Iron, Stainless Steel, Carbon Steel |

| Safe for Use With | Water, Oil, Gas, Steam, Various Chemicals |

| Handle Type | Lever, Gear Operator, Handwheel |

| Handle Material | Stainless Steel, Carbon Steel, Aluminum |

| Maximum Working Pressure (psi) | Up to 600 psi (for certain models) |

| Maximum Working Pressure (bar) | Up to 41 bar (for certain models) |

| Operating Pressure | Consult manufacturer’s specifications for specific operating pressures |

The Parameter of Grove Ball Valve

- Type: Grove Ball Valve

- Ball Material: Typically constructed from stainless steel or brass for durability and corrosion resistance.

- Attachment Type: Available in threaded or flanged configurations to suit different installation requirements.

- Thread Standard: Conforms to ANSI B1.20.1 or BSPP standards for compatibility with various piping systems.

- Thread Size: Offered in sizes ranging from 1/2″ to 4″ to accommodate different flow rates and applications.

- Body Material: Manufactured from high-quality materials such as cast iron, stainless steel, or carbon steel for robustness and reliability.

- Safe for Use With: Suitable for handling water, oil, gas, steam, and a variety of chemicals, providing versatility in applications.

- Handle Type: Equipped with a lever, gear operator, or handwheel for easy manual operation and flow control.

- Handle Material: Handles are typically made of stainless steel, carbon steel, or aluminum for strength and durability.

- Maximum Working Pressure (psi): Capable of handling pressures of up to 600 psi (depending on model and size) for reliable performance in demanding environments.

- Maximum Working Pressure (bar): Can withstand pressures of up to 41 bar (depending on model and size), ensuring safe operation in high-pressure systems.

- Operating Pressure: Operating pressure varies depending on specific model and size, refer to manufacturer’s specifications for precise details.

The Operation Theory of Grove Ball Valve

- Ball Rotation: The valve utilizes a spherical ball with a central hole, which can be rotated within the valve body.

- Flow Control: When the valve is in the open position, the ball aligns parallel to the direction of flow, allowing fluid to pass through the central hole.

- Closure: Rotating the ball perpendicular to the flow direction obstructs the passage, effectively shutting off the flow.

- Sealing Mechanism: The interface between the ball and the valve seat provides a tight seal, ensuring leak-free operation.

- Actuation: The valve can be operated manually using a lever, gear operator, or handwheel, allowing for precise control over the position of the ball.

- Maintenance: Regular maintenance, as specified in the Grove B5 Ball Valve Maintenance Manual, ensures optimal performance and longevity of the valve. This may include lubrication, inspection of seals, and replacement of worn components.

- Safety Considerations: Proper installation, operation, and maintenance are essential for ensuring the safety of personnel and equipment. Adhering to the guidelines outlined in the maintenance manual is crucial to prevent accidents and maintain efficiency.

The Parameters Table of Grove Ball Valve

| Parameter | Details |

|---|---|

| Type | Ball Valve |

| Ball Material | Stainless Steel or Brass |

| Valve Body Material | Cast Iron, Stainless Steel, Carbon Steel |

| Stem Material | Stainless Steel or Carbon Steel |

| Seat Material | PTFE (Teflon), RPTFE (Reinforced PTFE), or Metal (Stainless Steel) |

| Connection Type | Threaded or Flanged |

| Thread Standard | ANSI B1.20.1 or BSPP |

| Thread Size | 1/2″, 3/4″, 1″, 1-1/4″, 1-1/2″, 2″, 2-1/2″, 3″, 4″ |

| Handle Type | Lever, Gear Operator, Handwheel |

| Handle Material | Stainless Steel, Carbon Steel, Aluminum |

| Maximum Working Pressure (psi) | Up to 600 psi (depending on model and size) |

| Maximum Working Pressure (bar) | Up to 41 bar (depending on model and size) |

| Operating Temperature | Varies depending on ball and seat material, typically up to 400°F (204°C) |

| Suitable Media | Water, Oil, Gas, Steam, Various Chemicals |

| Certifications | API 6D, API 607, ISO 9001 |