The Applications of Cryogenic Valves

The Application of Cryogenic Valves

Certainly! Here’s a concise introduction to Cryogenic Valves incorporating the given keywords:

Cameron offers a range of high-quality cryogenic valves tailored for extreme temperature applications. Designed to operate in extremely low temperatures, these valves ensure reliable performance in cryogenic environments. The cryogenic ball valve is a popular choice for applications requiring precise flow control at low temperatures, offering tight shut-off and minimal leakage. Additionally, the cryogenic solenoid valve provides efficient on/off control of cryogenic fluids, enhancing system safety and reliability. Cameron’s commitment to innovation and quality makes their cryogenic valves ideal for industries such as aerospace, medical, and industrial gas processing, where the handling of liquefied gases and cryogenic fluids is essential for various applications.

What Are The Types Of Cryogenic Valves?

- Cryogenic Ball Valves: These valves feature a spherical closure unit (the ball) that rotates to control flow. Cryogenic ball valves are popular due to their tight shut-off capabilities and minimal leakage, making them suitable for applications requiring precise flow control in cryogenic conditions.

- Cryogenic Gate Valves: Gate valves use a gate or wedge-shaped disc to control flow. Cryogenic gate valves are designed to withstand low temperatures and offer reliable performance in cryogenic applications where on/off flow control is required.

- Cryogenic Globe Valves: Globe valves regulate flow by moving a plug against or away from the flow port. Cryogenic globe valves are used in applications requiring precise flow regulation and tight shut-off capabilities at low temperatures.

- Cryogenic Butterfly Valves: These valves feature a rotating disc (the butterfly) to control flow. Cryogenic butterfly valves are compact and lightweight, making them suitable for applications where space is limited, and they offer reliable performance in cryogenic environments.

- Cryogenic Check Valves: Check valves allow flow in one direction and prevent backflow. Cryogenic check valves are designed to operate effectively in low-temperature conditions and prevent the reverse flow of cryogenic fluids.

What Is Cryogenic Valves?

Cryogenic Valves are specialized valves designed to withstand and operate in extremely low-temperature environments. These valves are engineered with materials and construction methods that can endure the challenges posed by cryogenic fluids, such as liquefied gases and supercooled liquids. Cryogenic Valves are crucial components in industries dealing with cryogenic applications, including aerospace, medical, and industrial gas processing, where precise flow control and tight shut-off capabilities are essential for safe and efficient operations.

How Does Cryogenic Valves work?

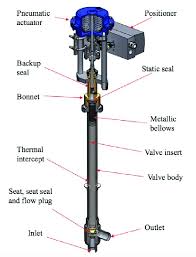

Cryogenic Valves operate by utilizing specialized materials and design features to function effectively in extremely low-temperature environments. When a cryogenic fluid flows through the valve, its components, such as the ball, gate, or disc, move to regulate the flow. These valves are engineered to maintain their integrity and performance even at temperatures below -150°C (-238°F), ensuring reliable flow control and tight shut-off capabilities in cryogenic applications.

Features of Cryogenic Valves

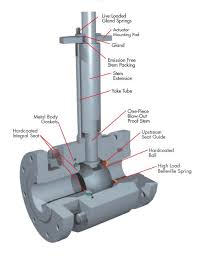

- Specialized Materials: Cryogenic Valves are constructed using materials such as stainless steel, brass, or aluminum specifically chosen for their ability to withstand low temperatures without compromising performance.

- Low-Temperature Design: These valves are designed with features such as extended bonnets, stem extensions, and specialized seals to prevent freezing and maintain functionality in cryogenic environments.

- Tight Shut-off: Cryogenic Valves offer tight shut-off capabilities to prevent leakage and ensure safe handling of cryogenic fluids, minimizing the risk of accidents and equipment damage.

- Precision Flow Control: They provide precise flow control even at extremely low temperatures, allowing for accurate regulation of fluid flow rates in cryogenic applications.

- Reliability: Cryogenic Valves are reliable and built to withstand the challenges of cryogenic conditions, ensuring consistent performance and long-term durability.

- Safety Features: Many Cryogenic Valves are equipped with safety features such as pressure relief devices and emergency shut-off mechanisms to enhance system safety and protect personnel and equipment.

- Versatility: They are versatile and can be used in various industries and applications, including aerospace, medical, and industrial gas processing, where cryogenic fluids are handled.

- Compliance: Cryogenic Valves comply with industry standards and regulations for cryogenic applications, ensuring they meet performance and safety requirements.

Advantages of Cryogenic Valves

- Low-Temperature Compatibility: Cryogenic Valves are specifically designed to operate effectively in extremely low-temperature environments, ensuring reliable performance even in sub-zero conditions.

- Tight Shut-off: These valves offer tight shut-off capabilities, minimizing the risk of leakage and ensuring safe handling of cryogenic fluids, which is crucial for preventing accidents and equipment damage.

- Precision Flow Control: Cryogenic Valves provide precise flow control, allowing for accurate regulation of fluid flow rates in cryogenic applications, ensuring optimal performance and efficiency.

- Durable Construction: They are constructed using specialized materials and design features to withstand the challenges posed by cryogenic temperatures, ensuring long-term durability and reliability.

- Versatility: Cryogenic Valves are versatile and can be used in various industries and applications where cryogenic fluids are handled, including aerospace, medical, and industrial gas processing.

- Safety Features: Many Cryogenic Valves are equipped with safety features such as pressure relief devices and emergency shut-off mechanisms, enhancing system safety and protecting personnel and equipment.

- Compliance: Cryogenic Valves comply with industry standards and regulations for cryogenic applications, ensuring they meet performance and safety requirements.

The Specifications of Cryogenic Valves

| Specification | Details |

|---|---|

| Type | Cryogenic Valve |

| Ball Material | Stainless Steel |

| Attachment Type | Threaded |

| Thread Standard | NPT (National Pipe Thread) |

| Thread Size | 3/4 inch |

| Body Material | Brass |

| Safe for Use With | Cryogenic Fluids (e.g., Liquid Nitrogen) |

| Handle Type | Lever |

| Handle Material | Aluminum |

| Maximum Working Pressure (psi) | 600 psi |

| Maximum Working Pressure (bar) | 41.37 bar |

| Operating Pressure | 20-150 psi |

The Parameter of Cryogenic Valves

- Type: Cryogenic Valve

- Ball Material: Stainless Steel

- Attachment Type: Threaded

- Thread Standard: NPT (National Pipe Thread)

- Thread Size: 3/4 inch

- Body Material: Brass

- Safe for Use With: Cryogenic Fluids (e.g., Liquid Nitrogen)

- Handle Type: Lever

- Handle Material: Aluminum

- Maximum Working Pressure (psi): 600 psi

- Maximum Working Pressure (bar): 41.37 bar

- Operating Pressure: 20-150 psi

The Operation Theory of Cryogenic Valves

- Cryogenic Ball Valves: These valves utilize a spherical closure unit (the ball) to control flow. When the valve is open, the ball rotates to allow fluid to pass through, and when closed, it seals against the valve seat to prevent flow. This operation ensures precise flow control in cryogenic applications.

- Cryogenic Check Valve: Check valves allow flow in one direction and prevent backflow. In cryogenic check valves, when the fluid flows in the correct direction, it lifts the valve’s internal disc, allowing flow. If there’s any reverse flow or pressure drop, the disc closes, preventing fluid from flowing backward.

- Cryogenic Relief Valve: Relief valves are designed to relieve excess pressure in a system. In cryogenic relief valves, when the pressure exceeds the set limit, the valve opens to release the excess fluid or gas, thus preventing overpressure and maintaining system safety.

The Parameters Table of Cryogenic Valves

| Parameter | Details |

|---|---|

| Type | Cryogenic Valve |

| Body Material | Stainless Steel, Brass, Aluminum, etc. |

| Ball Material | Stainless Steel, Brass, Aluminum, etc. |

| Seal Material | PTFE (Polytetrafluoroethylene), Graphite, etc. |

| Stem Material | Stainless Steel, Brass, Aluminum, etc. |

| Seat Material | PTFE (Polytetrafluoroethylene), Stainless Steel, etc. |

| Bonnet Material | Stainless Steel, Brass, Aluminum, etc. |

| Handle Material | Aluminum, Stainless Steel, Brass, etc. |

| Attachment Type | Threaded, Flanged, Welded, etc. |

| Thread Standard | NPT (National Pipe Thread), BSPT (British Standard Pipe Thread), etc. |

| Thread Size | Various sizes (e.g., 1/2 inch, 3/4 inch, etc.) |

| Maximum Working Pressure (psi) | Varies based on model and size (e.g., 600 psi, 1000 psi, etc.) |

| Maximum Working Pressure (bar) | Varies based on model and size (e.g., 41.37 bar, 68.95 bar, etc.) |

| Operating Temperature Range | Varies based on materials and design (e.g., -196°C to 120°C) |