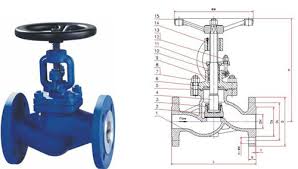

DIN Globe Valve

The Application of DIN Globe Valve

Introducing the DIN Globe Valve, a pivotal component in fluid control systems. Designed to meet stringent standards, including carbon steel DIN standard globe valve specifications, it offers robust performance in various applications. With options like the bellows seal DIN carbon steel globe valve for enhanced sealing and the cast steel DIN angle globe valve for specialized installations, these valves ensure reliability and durability. Manufactured by the trusted brand Cameron, these valves excel in industries ranging from petrochemicals to power generation, providing efficient fluid regulation and minimizing leakage risks.

What Are The Types Of DIN Globe Valve?

- Bellows Seal DIN Globe Valve:

- Features a bellows seal design for enhanced sealing performance, ideal for applications requiring tight shut-off and minimal leakage.

- Carbon Steel DIN Standard Globe Valve:

- Manufactured in accordance with DIN standards for carbon steel valves, offering durability and reliability in various industrial environments.

- Cast Steel DIN Angle Globe Valve:

- Designed with an angled body for specific installation requirements, providing flexibility and efficient fluid control in tight spaces or unique piping configurations.

What Is DIN Globe Valve?

The DIN Globe Valve is a type of industrial valve designed to regulate fluid flow within pipelines. Complying with DIN standards, it features a globe-shaped body with an internal mechanism that controls the flow by raising or lowering a disc. This design enables precise flow regulation and tight shut-off, making it suitable for various industries such as oil and gas, chemical, and power generation. The valve’s robust construction, typically in materials like carbon steel, ensures durability and reliable performance in demanding environments.

How to Select the Right DIN Globe Valve?

Selecting the appropriate DIN Globe Valve involves considering several factors. First, determine the operating conditions such as pressure, temperature, and fluid compatibility. Then, assess the valve size and connection type to ensure compatibility with the existing pipeline. Additionally, consider any special features required, such as bellows seals for enhanced sealing or angle designs for tight spaces. Consulting with a knowledgeable supplier can help ensure the chosen valve meets specific application needs effectively.

Features of DIN Globe Valve

- Robust Construction:

- Constructed from durable materials such as carbon steel or cast steel, ensuring longevity and reliability in demanding environments.

- Compliance with Standards:

- Manufactured to meet DIN standards, guaranteeing quality and consistency in performance.

- Versatile Applications:

- Suitable for a wide range of industries including oil and gas, chemical, and power generation, due to its versatile functionality.

- Precise Flow Control:

- Globe valve design enables precise regulation of fluid flow, allowing for accurate adjustment and control.

- Tight Shut-off:

- Provides a tight shut-off, minimizing leakage and ensuring system integrity during operation.

- Options for Specialized Needs:

- Available with bellows seals for enhanced sealing performance or angle designs for installation in tight spaces, catering to specialized requirements.

- Easy Maintenance:

- Designed for ease of maintenance, facilitating quick inspection and repair to minimize downtime.

Advantages and Disadvantages of DIN Globe Valve

Certainly, here are the advantages and disadvantages of the DIN Globe Valve presented in a point-by-point format:

Advantages:

- Precise Flow Control:

- Enables accurate regulation of fluid flow, ensuring optimal system performance.

- Versatility:

- Suitable for a wide range of applications across different industries due to its adaptable design.

- Robust Construction:

- Constructed from durable materials, providing longevity and reliability in harsh operating conditions.

- Tight Shut-off:

- Offers a tight seal when closed, minimizing leakage and ensuring system integrity.

- Compliance with Standards:

- Manufactured to meet DIN standards, ensuring quality and consistency in performance.

Disadvantages:

- Higher Cost:

- Initial investment costs may be higher compared to other types of valves, especially for specialized features such as bellows seals.

- Complexity:

- Globe valves can be more complex in design compared to simpler valve types, requiring careful selection and maintenance.

- Limited Flow Capacity:

- May have limitations in handling high flow rates compared to other valve types like gate valves.

- Pressure Drop:

- Globe valves can cause pressure drop across the valve, affecting system efficiency in high-pressure applications.

- Maintenance Requirements:

- Requires periodic maintenance to ensure continued performance, which may result in downtime and operational costs.

The Specifications of DIN Globe Valve

| Specification | Details |

|---|---|

| Type | DIN Globe Valve |

| Ball Material | Stainless Steel |

| Attachment | Fl |

| Thre | DI |

| Thread S | M10 |

| Body Material | Carbon Steel |

| Safe for Use With | Wat |

| Handle Type | Handwheel |

| Handle Material | Carbon Ste |

| Maxim | 250 psi |

| Maximum Working Pressure | 16.3 bar |

| Operating Pressure | 5-100 psi |

The Installation Steps for DIN Globe Valve

- Prepare the Installation Site:

- Choose a suitable location in the pipeline where the DIN Globe Valve will be installed.

- Ensure the area is clean and free from debris to prevent contamination.

- Check Valve Compatibility:

- Verify that the valve size, pressure rating, and connection type match the requirements of the pipeline.

- Shut Down the System:

- Turn off the flow of media (water, oil, gas, etc.) within the pipeline to prevent leaks during installation.

- Prepare the Valve:

- Inspect the valve to ensure it is free from damage and defects.

- Apply any necessary sealant or thread tape to the valve threads to ensure a tight seal.

- Install the Valve:

- Align the valve with the designated installation point on the pipeline.

- Securely attach the valve using appropriate bolts or fasteners, ensuring it is properly aligned.

- Tighten Connections:

- Use a wrench to tighten the valve connections, ensuring they are snug but not over-tightened to avoid damage.

- Test for Leaks:

- Gradually restore the flow of media within the pipeline.

- Inspect the valve and surrounding connections for any signs of leakage, and address any issues promptly.

- Document Installation:

- Keep records of the installation process, including the date, location, and any relevant notes for future reference.

The Operation Theory of DIN Globe Valve

- DIN Globe Valve Operation Theory:

- The DIN Globe Valve operates on the principle of linear motion, utilizing a globe-shaped disc or plug to regulate fluid flow within the pipeline.

- When the valve is open, the disc or plug is lifted away from the seat, allowing fluid to pass through the valve.

- Conversely, when the valve is closed, the disc or plug is lowered onto the seat, blocking the flow of fluid and providing tight shut-off.

- Cast Steel DIN Globe Valves:

- Cast steel DIN Globe Valves are constructed from cast steel materials, offering durability and reliability in various industrial applications.

- They adhere to DIN standards, ensuring quality and performance consistency.

- These valves are suitable for applications requiring robust construction and resistance to corrosion and high temperatures.

- China DIN Bellows Globe Valves:

- China DIN Bellows Globe Valves feature a bellows seal design for enhanced sealing performance, minimizing the risk of leakage.

- They are manufactured in China and comply with DIN standards, meeting quality and performance requirements.

- These valves are particularly suitable for applications requiring tight shut-off and leakage prevention, such as high-pressure or high-temperature environments.