Double Eccentric Plug Valve

The Application of Double Eccentric Plug Valve

Introducing the Double Eccentric Plug Valve, an advanced variation of the eccentric plug valve. Eccentric plug valves are renowned for their reliable sealing capabilities and minimal maintenance requirements. With Cameron’s expertise, the Double Eccentric Plug Valve offers enhanced performance and durability, making it ideal for demanding applications. Its unique design ensures tight shut-off, even in high-pressure and high-temperature conditions. Used extensively in industries such as oil and gas, petrochemicals, and power generation, Cameron’s Double Eccentric Plug Valve stands as a trusted solution for critical flow control needs.

What Are The Types Of Double Eccentric Plug Valve?

- Metal-seated Double Eccentric Plug Valve: Designed with metal seating surfaces for enhanced durability and resistance to high temperatures and abrasive media.

- Soft-seated Double Eccentric Plug Valve: Features soft elastomeric seating materials for reliable sealing and low torque operation, suitable for applications with less abrasive media.

- High-Performance Double Eccentric Plug Valve: Engineered for high-pressure and high-temperature applications, offering superior sealing performance and extended service life.

- Triple Offset Double Eccentric Plug Valve: Incorporates an additional offset to the rotational axis of the plug, providing bubble-tight shut-off and reduced wear.

- Cryogenic Double Eccentric Plug Valve: Designed to withstand extreme low temperatures, maintaining sealing integrity in cryogenic fluid handling systems.

What Is Double Eccentric Plug Valve?

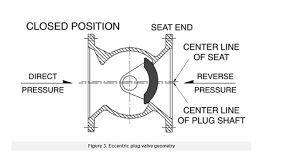

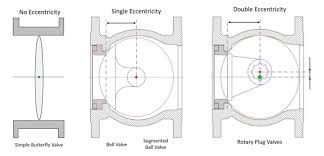

A Double Eccentric Plug Valve is an advanced type of plug valve characterized by its double offset design. Unlike traditional plug valves, it features two offsets: one in the shaft and another in the sealing face. This design reduces friction during operation and improves sealing performance, making it ideal for applications requiring tight shut-off and minimal leakage. Double Eccentric Plug Valves are commonly used in industries such as oil and gas, chemical processing, and water treatment for precise flow control and reliable operation.

How to Select the Right Double Eccentric Plug Valve?

To select the right Double Eccentric Plug Valve, consider factors like the pressure rating, temperature range, media compatibility, and end connections. Ensure the valve meets industry standards and specifications while also considering the specific requirements of your application. Additionally, opt for reputable brands like Cameron for quality assurance and reliability.

Features of Double Eccentric Plug Valve

- Double Offset Design: Features two offsets in the shaft and sealing face, reducing friction and improving sealing performance.

- Bubble-Tight Shut-Off: Provides excellent sealing capabilities, ensuring minimal leakage and precise flow control.

- High Temperature Resistance: Constructed from materials capable of withstanding high temperatures, making it suitable for a wide range of industrial applications.

- Corrosion Resistance: Engineered with corrosion-resistant materials, ensuring durability and longevity in corrosive environments.

- Low Torque Operation: Requires minimal torque to operate, reducing wear and extending service life.

- Versatile Applications: Suitable for various industries including oil and gas, chemical processing, and water treatment, offering reliable flow control solutions.

- Bi-Directional Flow: Allows for flow in both directions, providing flexibility in installation and operation.

- Ease of Maintenance: Designed for easy maintenance and repair, minimizing downtime and associated costs.

Advantages and Disadvantages of Double Eccentric Plug Valve

Advantages

- Improved Sealing: The double offset design enhances sealing performance, ensuring bubble-tight shut-off and minimal leakage.

- Low Friction: Reduced friction in the shaft and sealing face results in smooth operation and extended service life.

- Versatile Applications: Suitable for a wide range of industries and applications due to its robust construction and reliable performance.

- High Temperature Resistance: Capable of withstanding high temperatures, making it suitable for use in demanding environments.

Disadvantages

- Higher Cost: Double Eccentric Plug Valves may have a higher initial cost compared to standard plug valves due to their advanced design and construction.

- Complex Design: The double offset design adds complexity to the valve, potentially increasing maintenance requirements and associated costs.

- Limited Availability: Depending on the manufacturer and supplier, Double Eccentric Plug Valves may have limited availability compared to standard plug valves.

The Specifications of Double Eccentric Plug Valve

| Specification | Details |

|---|---|

| Type | Double Eccentric Plug Valve |

| Ball Material | Stainless Steel or Carbon Steel |

| Attachment Type | Flanged or Threaded |

| Thread Standard | ANSI, DIN, JIS, or others |

| Thread Size | 1/2 inch to 24 inches |

| Body Material | Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel, or others |

| Safe for Use With | Water, Oil, Gas, Chemicals, etc. |

| Handle Type | Lever, Gear, or Actuator |

| Handle Material | Carbon Steel, Stainless Steel, or Aluminum |

| Maximum Working Pressure (psi) | Up to 1500 psi |

| Maximum Working Pressure (bar) | Up to 103.42 bar |

| Operating Pressure | Typically 0-300 psi (0-20.68 bar) |

The Installation Steps for Double Eccentric Plug Valve

- Prepare Work Area: Clear the area around the installation site to ensure easy access to the piping system.

- Shut Off Supply: Turn off the main supply of fluid (water, gas, etc.) to the system where the valve will be installed.

- Relieve Pressure: If applicable, relieve any pressure in the system by opening nearby valves or faucets.

- Select Proper Location: Choose the appropriate location for installing the valve, considering factors such as accessibility and alignment with the piping system.

- Prepare Pipes: Clean and deburr the ends of the pipes where the valve will be connected to ensure a proper seal.

- Apply Thread Sealant: Apply thread sealant or tape to the male threads of the valve to prevent leaks.

- Attach Valve: Connect the Double Eccentric Plug Valve to the pipes using the appropriate attachment type (flanged or threaded), ensuring a tight connection.

- Position Valve: Ensure the valve is positioned correctly with the flow direction indicated by the arrow on the valve body.

- Tighten Connections: Use a wrench to tighten the valve connections securely, but avoid over-tightening to prevent damage.

- Check Alignment: Verify that the valve is aligned properly with the piping system to prevent stress or strain on the connections.

- Turn On Supply: Gradually turn on the main supply of fluid and check for any leaks at the valve connections.

- Test Operation: Test the valve by operating it manually or using a control system to ensure proper opening and closing.

The Operation Theory of Double Eccentric Plug Valve

- Double Offset Design: Double Eccentric Plug Valves feature two offsets in the shaft and sealing face, reducing friction and enhancing sealing performance.

- Rotation Mechanism: When the valve handle or actuator is turned, the plug rotates within the valve body, controlling the flow of fluid.

- Sealing Action: As the plug rotates, the eccentric design ensures the sealing surface moves away from the seat gradually, reducing wear and friction.

- Bubble-Tight Shut-Off: The offset design allows the plug to make a tight seal against the seat, providing bubble-tight shut-off even in high-pressure applications.

- Regulating Flow: By controlling the degree of rotation, the valve regulates the flow of fluid through the system, offering precise flow control.

- Versatile Applications: Double Eccentric Plug Valves are suitable for various industries and applications, including water treatment, oil and gas, and chemical processing.

Dezurik Eccentric Plug Valve

- Similar Operation: The Dezurik Eccentric Plug Valve operates on the same principle as the Double Eccentric Plug Valve, with a double offset design for improved sealing and control.

- Durable Construction: Built with high-quality materials, Dezurik Eccentric Plug Valves offer durability and reliability in demanding environments.

- Wide Range of Options: Dezurik offers a wide range of configurations and options for Eccentric Plug Valves, allowing customization to meet specific application requirements.

- Trusted Brand: Dezurik is a trusted manufacturer known for its innovative valve solutions and commitment to quality and performance.