CV of Valves

What Is CV of Valves?

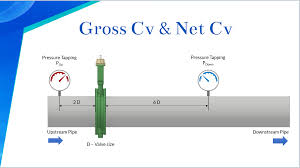

CV of a valve, often referred to as the flow coefficient, is a measure of the valve’s capacity to allow fluid flow. It represents the flow rate of water at a specified pressure drop across the valve. Calculate CV of control valve involves determining the flow coefficient based on the valve’s characteristics such as size, shape, and opening position. This value is crucial in valve selection and sizing for a given application, helping engineers and designers ensure optimal flow control and system performance.

How Does Valves work?

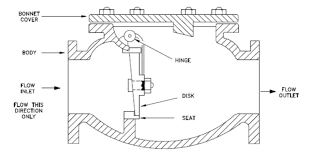

Valves control the flow of fluids or gases within a system by opening, closing, or partially obstructing the passage. They operate by using mechanisms such as rotating discs, sliding gates, or flexible diaphragms to regulate the flow rate and direction. When valves are opened, fluid or gas can pass through freely, while closing them restricts or stops the flow entirely. This enables precise control over the flow within pipelines, allowing for adjustments to pressure, temperature, and flow rate to meet specific process requirements.

The Importance of The CV of Valves

The rated CV of a valve signifies its ability to regulate flow rates at specific pressure differentials, crucial for ensuring efficient fluid control. Engineers calculate CV of valves to accurately size and select valves for desired flow rates and system conditions. This parameter plays a pivotal role in optimizing system performance, minimizing energy consumption, and maintaining process stability. Accurate CV determination enables precise matching of valve characteristics to application requirements, facilitating smooth operation, enhanced safety, and improved overall efficiency in various industrial processes.

How to Calculate The CV of Valves

- Gather Data: Collect information on the valve size, type, pressure drop, and fluid properties.

- Understand CV Equation: Familiarize yourself with the formula: CV = Q / √ΔP, where Q is the flow rate (in gallons per minute or cubic meters per hour) and ΔP is the pressure drop (in psi or bar).

- Determine Flow Rate: Calculate or determine the required flow rate based on system requirements and operating conditions.

- Determine Pressure Drop: Calculate or estimate the pressure drop across the valve under the given flow conditions.

- Apply the Formula: Plug the flow rate and pressure drop values into the CV equation and solve for CV.

- Validate Calculation: Double-check calculations and ensure units are consistent to obtain accurate CV values.

- Compare with Rated CV: Compare the calculated CV with the valve’s rated CV to ensure compatibility and proper sizing for the application.

- Adjust if Necessary: If the calculated CV differs significantly from the rated CV, consider adjusting valve selection or system parameters to achieve desired performance.