Duckbill Check Valve

The Application of Duckbill Check Valve

Introducing the Flowserve Duckbill Check Valve, a top-tier choice for diverse applications requiring reliable fluid control. Designed with precision engineering, duckbill check valves ensure unidirectional flow, preventing backflow and contamination. Crafted from high-grade materials, the rubber duckbill check valve guarantees durability and longevity, even in harsh environments.

With its innovative design, the 1 duckbill check valve offers seamless operation, eliminating the need for maintenance and manual adjustments. From wastewater management to industrial processes, this valve excels in various sectors, providing efficient flow control and enhancing system performance. Trust Flowserve for unparalleled quality and efficiency in fluid handling solutions.

What Is Duckbill Check Valve?

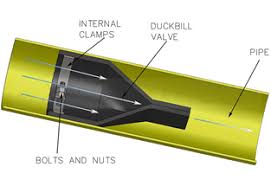

A Duckbill Check Valve is a specialized valve designed to allow fluid to flow in only one direction while preventing backflow. Its unique shape resembles a duck’s bill, hence the name. The valve opens under forward pressure, allowing fluid to pass through, and closes tightly when the flow stops, preventing reverse flow and ensuring system integrity. These valves find applications in various industries where reliable one-way flow control is crucial, such as wastewater systems, drainage systems, and pumping stations.

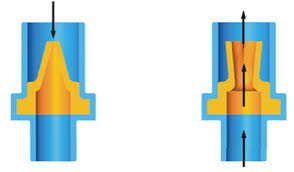

How Does Duckbill Check Valve work?

A Duckbill Check Valve operates based on its unique design. When fluid flows in the intended direction, the pressure forces the flexible bill open, allowing passage. Once the flow stops or reverses, the bill closes, creating a tight seal and preventing backflow. This mechanism ensures efficient one-way flow control without the need for any external power source or manual intervention.

Features of Duckbill Check Valve

- Reliable Performance: Duckbill check valves offer consistent and dependable operation, ensuring uninterrupted flow in one direction while effectively preventing backflow.

- Versatile Applications: These valves find utility across various industries including wastewater management, stormwater systems, sewage treatment plants, and industrial processes, showcasing their adaptability.

- Maintenance-Free Design: With no moving parts to wear out or require regular maintenance, rubber duckbill check valves offer hassle-free operation and long-term reliability.

- Excellent Sealing: The unique design of the duckbill shape provides an effective seal against reverse flow, minimizing leakage and ensuring system integrity.

- Durability: Constructed from high-quality rubber or other resilient materials, 1 duckbill check valve exhibits excellent resistance to corrosion, abrasion, and chemical degradation, ensuring extended service life.

- Cost-Effective Solution: Their robust construction and minimal maintenance requirements make duckbill check valves a cost-effective choice for fluid control applications, providing long-term savings.

Advantages of Duckbill Check Valve

- Efficient Flow Control: Duckbill check valves ensure smooth and efficient flow regulation by allowing fluid to move in one direction while preventing backflow, minimizing system disruptions.

- No Mechanical Parts: With no mechanical components like hinges or springs, these valves offer a simple and reliable design, reducing the risk of mechanical failure and eliminating the need for frequent maintenance.

- Self-Cleaning Action: The duckbill shape of the valve naturally prevents debris buildup and sediment accumulation, promoting self-cleaning action and reducing the risk of clogging.

- Versatile Installation Options: Duckbill check valves can be installed horizontally, vertically, or at an angle without compromising performance, offering flexibility in system design and layout.

- Silent Operation: Due to their design, these valves operate quietly without generating noise or vibration, making them suitable for applications where noise reduction is important.

- Excellent Sealing Properties: The duckbill design provides a tight seal against reverse flow, minimizing leakage and ensuring system efficiency and reliability.

- Long Service Life: Constructed from durable materials such as rubber or synthetic elastomers, duckbill check valves offer excellent resistance to corrosion, abrasion, and chemical damage, resulting in a long service life.

The Specifications of Duckbill Check Valve

| Specifications | Details |

|---|---|

| Type | Duckbill Check Valve |

| Ball Material | N/A |

| Attachment Type | Flanged, Socket Weld, Threaded, etc. |

| Thread Standard | ANSI, DIN, BS, etc. |

| Thread Size | Various sizes available |

| Body Material | Rubber, PVC, Stainless Steel, etc. |

| Safe for Use With | Water, Air, Chemicals, etc. |

| Handle Type | N/A |

| Handle Material | N/A |

| Maximum Working Pressure (psi) | Up to [specific value] |

| Maximum Working Pressure (bar) | Up to [specific value] |

| Operating Pressure | Varies based on specifications |

The Parameter of Duckbill Check Valve

- Type: Duckbill Check Valve

- Ball Material: Not applicable

- Attachment Type: Various options available including flanged, socket weld, threaded, etc.

- Thread Standard: Can be ANSI, DIN, BS, etc. depending on the model.

- Thread Size: Available in various sizes to suit different piping requirements.

- Body Material: Constructed from materials such as rubber, PVC, stainless steel, etc.

- Safe for Use With: Suitable for use with water, air, chemicals, and other compatible fluids.

- Handle Type: Typically does not have a handle.

- Handle Material: Not applicable.

- Maximum Working Pressure (psi): Up to a specific value depending on the model.

- Maximum Working Pressure (bar): Up to a specific value depending on the model.

- Operating Pressure: Operating pressure varies based on the specific model and application.

The Operation Theory of Duckbill Check Valve

The operation theory of a Duckbill Check Valve is based on its unique design, particularly its distinctive duckbill shape. Here’s how it works:

- Unidirectional Flow: The 4 duckbill check valve allows fluid to flow in only one direction, preventing backflow.

- Flexible Design: The check valve duckbill features a flexible bill that opens when fluid flows in the desired direction.

- Closure Mechanism: When the flow stops or reverses, the bill of the valve collapses or contracts, creating a seal against the flow, thereby preventing reverse flow.

- No Moving Parts: Unlike traditional check valves with moving parts like springs or hinges, the duckbill check valve operates solely based on the fluid pressure, making it highly reliable and durable.

- Efficient Flow Control: This design ensures efficient flow control without the need for manual intervention or external power sources, making it ideal for various applications where reliable one-way flow is critical.

The Parameters Table of Duckbill Check Valve

| Parameters | Details |

|---|---|

| Type | Duckbill Check Valve |

| Ball Material | N/A |

| Attachment Type | Flanged, Socket Weld, Threaded, etc. |

| Thread Standard | ANSI, DIN, BS, etc. |

| Thread Size | Various sizes available |

| Body Material | Rubber, EPDM, Silicone, PVC, Stainless Steel, etc. |

| Duckbill Material | Rubber, EPDM, Silicone, etc. |

| Seat Material | Rubber, EPDM, Silicone, etc. |

| Reinforcement Material | Nylon, Polyester, Metal, etc. |

| Safe for Use With | Water, Air, Chemicals, etc. |

| Maximum Working Pressure (psi) | Up to [specific value] |

| Maximum Working Pressure (bar) | Up to [specific value] |

| Operating Pressure | Varies based on specifications |