Four Various Industrial Uses for Butterfly Valves

The Application of Butterfly Valves

Cameron offers a range of Butterfly Valves suitable for various industrial applications. When comparing lug vs wafer butterfly valve designs, both offer advantages: lug valves have threaded inserts for easy installation, while wafer valves are lighter and more compact. Similarly, the debate over wafer vs lug butterfly valve revolves around installation preferences and space constraints. Butterfly valves function differently from gate valves, utilizing a disc to control flow rather than a gate. They find applications in industries such as oil and gas, water treatment, HVAC, and chemical processing. Whether selecting between lug and wafer designs or considering butterfly valves over gate valves, Cameron provides reliable solutions tailored to specific industrial needs.

What Are The Types Of Butterfly Valves?

- Concentric Butterfly Valve: In this type, the stem is centered in the middle of the valve disc, resulting in uniform sealing and minimal friction during operation.

- Eccentric Butterfly Valve: The stem is offset from the centerline of the valve disc in eccentric butterfly valves. This design reduces wear and tear on the sealing mechanism, making it suitable for high-pressure and high-temperature applications.

- High-Performance Butterfly Valve: These valves are designed to withstand higher pressures and temperatures compared to standard butterfly valves. They often feature metal-to-metal seals and reinforced construction for enhanced performance and durability.

- Double Offset Butterfly Valve: This type of valve has two offsets: one in the stem and one in the disc. Double offset butterfly valves offer improved sealing performance and reduced operating torque, making them suitable for demanding applications.

- Triple Offset Butterfly Valve: Triple offset butterfly valves feature three offsets: one in the stem, one in the disc, and one in the seat. This design provides bubble-tight sealing and excellent resistance to wear and corrosion, making them ideal for critical applications such as oil and gas, petrochemical, and power generation.

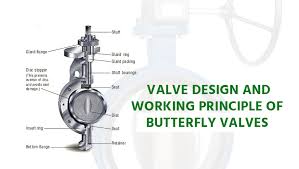

What Is Butterfly Valves?

Butterfly Valves are mechanical valves used to control the flow of fluids in piping systems. They consist of a circular disc mounted on a rotating shaft, which acts as the valve closure element. When the valve is open, the disc is turned parallel to the flow direction, allowing fluid to pass through. Conversely, when the valve is closed, the disc is rotated perpendicular to the flow, blocking the passage of fluid. Butterfly Valves are widely used in various industries due to their compact design, low cost, and ease of operation. They are suitable for applications requiring quick shutoff and throttling of flow.

How Does Butterfly Valves work?

Butterfly Valves work by rotating a disc or plate within the flow of fluid to control its passage. When the valve is open, the disc is positioned parallel to the flow direction, allowing fluid to pass through with minimal obstruction. To close the valve, the disc is rotated perpendicular to the flow, effectively blocking the passage of fluid. This simple yet effective mechanism allows for quick and efficient control of flow rates in piping systems, making Butterfly Valves suitable for a wide range of applications in various industries.

Features of Butterfly Valves

- Versatility: Butterfly Valves are versatile and can be used for various applications, including isolating or regulating flow in water treatment plants, HVAC systems, and industrial processes.

- Compact Design: They have a compact and lightweight design, making them easy to install and suitable for applications where space is limited.

- Low Pressure Drop: Due to their streamlined flow path, Butterfly Valves offer low pressure drop compared to other types of valves, ensuring efficient flow control and energy savings.

- Quick Operation: They can be operated quickly and easily with a quarter-turn of the handle or actuator, allowing for rapid opening and closing of the valve.

- Cost-Effectiveness: Butterfly Valves are cost-effective solutions for flow control applications, offering a balance of performance and affordability.

- Bubble-Tight Sealing: Advanced designs, such as triple offset or high-performance butterfly valves, offer bubble-tight sealing, ensuring leak-free operation even in demanding applications.

- Minimal Maintenance: With fewer moving parts and simple construction, Butterfly Valves require minimal maintenance, reducing downtime and operational costs.

- Corrosion Resistance: They are available in a variety of materials, including stainless steel and corrosion-resistant alloys, making them suitable for use in corrosive environments.

Advantages of Butterfly Valves

- Quick Operation: Butterfly Valves can be opened or closed quickly with a quarter-turn of the handle or actuator, allowing for rapid flow control adjustments.

- Low Pressure Drop: Due to their streamlined design, Butterfly Valves offer low pressure drop compared to other types of valves, minimizing energy consumption and ensuring efficient flow control.

- Compact Design: They have a compact and lightweight construction, making them easy to install and suitable for applications where space is limited.

- Cost-Effectiveness: Butterfly Valves are generally more cost-effective than other types of valves, offering a balance of performance and affordability.

- Versatility: They can be used for various applications, including isolating or regulating flow in water treatment plants, HVAC systems, and industrial processes.

- Minimal Maintenance: With fewer moving parts and simple construction, Butterfly Valves require minimal maintenance, reducing downtime and operational costs.

- Bubble-Tight Sealing: Advanced designs, such as triple offset or high-performance butterfly valves, offer bubble-tight sealing, ensuring leak-free operation even in demanding applications.

- Corrosion Resistance: They are available in a variety of materials, including stainless steel and corrosion-resistant alloys, making them suitable for use in corrosive environments.

The Specifications of Butterfly Valves

| Specification | Details |

|---|---|

| Type | Butterfly Valve |

| Ball Material | Stainless Steel, Brass, Aluminum, etc. |

| Attachment Type | Lug, Wafer, Flanged |

| Thread Standard | N/A |

| Thread Size | N/A |

| Body Material | Ductile Iron, Cast Iron, Stainless Steel, etc. |

| Safe for Use With | Water, Air, Gas, Various Chemicals |

| Handle Type | Lever, Gear, Actuator |

| Handle Material | Aluminum, Stainless Steel, Brass, etc. |

| Maximum Working Pressure (psi) | Varies based on size and design |

| Maximum Working Pressure (bar) | Varies based on size and design |

| Operating Pressure | Varies based on application requirements |

The Parameter of Butterfly Valves

- Type: Butterfly Valve

- Ball Material: Stainless Steel, Brass, Aluminum, etc.

- Attachment Type: Lug, Wafer, Flanged

- Body Material: Ductile Iron, Cast Iron, Stainless Steel, etc.

- Safe for Use With: Water, Air, Gas, Various Chemicals

- Handle Type: Lever, Gear, Actuator

- Handle Material: Aluminum, Stainless Steel, Brass, etc.

- Maximum Working Pressure (psi): Varies based on size and design

- Maximum Working Pressure (bar): Varies based on size and design

- Operating Pressure: Varies based on application requirements

The Operation Theory of Butterfly Valves

- Butterfly Valve Operation Theory: Butterfly Valves operate by rotating a disc or plate within the flow of fluid to control its passage. When the valve is open, the disc is positioned parallel to the flow direction, allowing fluid to pass through with minimal obstruction. To close the valve, the disc is rotated perpendicular to the flow, effectively blocking the passage of fluid. This simple yet effective mechanism allows for quick and efficient control of flow rates in piping systems, making Butterfly Valves suitable for a wide range of applications in various industries.

- Gate Valve vs Butterfly Valve: While both Gate Valves and Butterfly Valves are used for flow control, they operate differently. Gate Valves use a gate or wedge-shaped disc to control flow by moving the gate up and down perpendicular to the flow direction. In contrast, Butterfly Valves use a rotating disc to control flow, providing a more compact and lightweight solution with quick operation.

- 4″ Butterfly Valve: A 4″ Butterfly Valve refers to a Butterfly Valve with a nominal size of 4 inches. These valves are commonly used in industrial applications for flow control in piping systems where a 4-inch diameter is required. They offer versatility, quick operation, and efficient flow control, making them suitable for a wide range of applications across industries.

The Parameters Table of Butterfly Valves

| Parameter | Details |

|---|---|

| Type | Butterfly Valve |

| Body Material | Ductile Iron, Cast Iron, Stainless Steel, etc. |

| Disc Material | Stainless Steel, Brass, Aluminum, etc. |

| Seat Material | EPDM, NBR, PTFE, etc. |

| Stem Material | Stainless Steel, Carbon Steel, etc. |

| Seal Material | EPDM, NBR, PTFE, etc. |

| O-ring Material | EPDM, NBR, Silicone, etc. |

| Handle Material | Aluminum, Stainless Steel, Brass, etc. |

| Attachment Type | Lug, Wafer, Flanged |

| Maximum Working Pressure (psi) | Varies based on size and design |

| Maximum Working Pressure (bar) | Varies based on size and design |

| Operating Temperature Range | Varies based on materials and design (e.g., -20°C to 200°C) |