Wedge Gate Valve

The Application of Wedge Gate Valve

The Wedge Gate Valve is a robust and reliable component used in various industries for fluid control. Unlike the wafer vs lug style butterfly valve or butterfly valve wafer vs lug, the Wedge Gate Valve offers superior sealing capabilities and is well-suited for high-pressure applications. It functions similarly to the KGC-BD knife gate valve, with a gate that moves vertically to regulate fluid flow. Known for its durability and tight shutoff, it is commonly used in demanding environments where precise flow control is essential. Industries such as oil and gas, water treatment, and power generation benefit from the performance and reliability of the Wedge Gate Valve, making it a preferred choice among engineers and operators.

What Is Wedge Gate Valve?

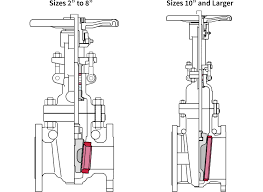

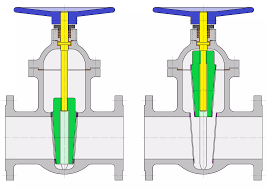

A Wedge Gate Valve is a type of linear motion valve that controls the flow of fluids in a pipeline. It features a gate with a wedge-shaped disc that moves perpendicular to the direction of flow to either fully open or fully close the valve. When the valve is fully open, the gate retracts into the valve body, allowing unrestricted flow of fluid. Conversely, when the valve is fully closed, the gate seals against matching seats in the valve body, preventing the flow of fluid. This design ensures a tight seal and minimal pressure drop across the valve. Wedge Gate Valves are commonly used in various industries, including oil and gas, water treatment, and power generation, where reliable and efficient flow control is essential.

Features of Wedge Gate Valve

- Wedge Gate Design: The wedge-shaped gate of ZECO gate valves ensures a tight seal during closure, enhancing overall sealing effectiveness.

- Lifting Stem: Featuring a lifting stem, ZECO valves allow easy visual inspection of the valve’s open or closed position from a distance. The stem and gate are securely connected via a t-groove, ensuring robust connection strength.

- Sealed Design: ZECO gate valves are equipped with a sealed design that enables packing replacement while the valve is fully open. This prevents unnecessary disassembly of the valve during packing replacement, saving time and resources.

- Anti-Collision Protection: ZECO valves are equipped with anti-collision protection on the flange surface to safeguard the valve’s convex surface during transportation, preventing damage from collisions.

The Specifications of Wedge Gate Valve

| Specification | Details |

|---|---|

| Type | Wedge Gate Valve |

| Body Material | Carbon Steel, Stainless Steel, Alloy Steel |

| Ball Material | N/A |

| Attachment Type | Flanged, Butt-weld, Socket-weld, Threaded |

| Thread Standard | ANSI, DIN, BS, JIS, API, Others |

| Thread Size | Various sizes ranging from DN15 to DN1200 |

| Safe for Use With | Various fluids including water, oil, gas, etc. |

| Handle Type | Handwheel, Gear Operated, Actuator |

| Handle Material | Carbon Steel, Stainless Steel, Alloy Steel |

| Maximum Working Pressure | Up to 2500 psi (172 bar) |

| Operating Pressure | As per application requirements |

The Parameter of Wedge Gate Valve

- Wedge Gate Design: Features a wedge-shaped gate that ensures tight sealing during closure, enhancing overall sealing effectiveness.

- Body Material Options: Available in carbon steel, stainless steel, and alloy steel options to suit various application requirements.

- Attachment Types: Compatible with different attachment types including flanged, butt-weld, socket-weld, and threaded connections, offering flexibility in installation.

- Thread Standard Compatibility: Supports various thread standards such as ANSI, DIN, BS, JIS, and API, ensuring compatibility with different piping systems.

- Thread Size Variability: Offered in a range of thread sizes from DN15 to DN1200, catering to diverse piping system requirements.

- Safe for Use With: Suitable for use with various fluids including water, oil, gas, and other compatible media.

- Handle Options: Available with different handle types such as handwheel, gear-operated, or actuator for convenient operation.

- Handle Material Variations: Handles can be constructed from carbon steel, stainless steel, or alloy steel, providing durability and reliability.

- Maximum Working Pressure: Capable of withstanding pressures up to 2500 psi (172 bar), ensuring reliable performance under high-pressure conditions.

- Operating Pressure: Operating pressure can be adjusted as per specific application requirements, providing flexibility in use.

The Operation Theory of Wedge Gate Valve

The operation theory of the Wedge Gate Valve involves a simple mechanism: when the valve is in the open position, the gate is lifted to allow fluid flow, and when closed, the gate is lowered to block flow. The wedge-shaped gate ensures a tight seal, enhancing sealing effectiveness. This valve operates efficiently, with minimal friction and wear on components. Industrial valve manufacturers design the Wedge Gate Valve to provide reliable performance in various applications, ensuring smooth fluid regulation. The valve’s operation principle is similar to other gate valves like the Intec Duoball Valve, offering efficient flow control in industrial settings.

The Parameters Table of Wedge Gate Valve

| Parameter | Description |

|---|---|

| Valve Type | Wedge Gate Valve |

| Body Material | Carbon Steel, Stainless Steel, Alloy Steel |

| Wedge Material | Stainless Steel, Carbon Steel, Alloy Steel |

| Seat Material | Metal or Soft (Resilient) |

| Stem Material | Stainless Steel, Carbon Steel, Alloy Steel |

| Bonnet Material | Carbon Steel, Stainless Steel, Alloy Steel |

| Connection Type | Flanged, Butt-Weld, Socket-Weld, Threaded |

| Size Range | DN15 to DN1200 (0.5″ to 48″) |

| Pressure Rating | ANSI Class 150 to 2500, PN16 to PN420 |

| Temperature Range | Up to 650°C (1200°F) |

| Actuation | Handwheel, Gear, Electric Actuator |

| End Connections | RF, RTJ, BW, SW, NPT |