Pneumatic Pressure-Balanced Cage Type Control Valve

The Application of Balanced Cage Type Control Valve

Introducing the Balanced Cage Type Control Valve: As a vital component in fluid control systems, the Balanced Valve by Cameron ensures precise regulation of flow rates and pressures. This advanced Control Valve design incorporates a balanced cage mechanism, optimizing performance across various operating conditions. Engineered to enhance efficiency and reliability, Cameron’s Balanced Cage Type Control Valve finds applications in industries requiring accurate flow control, such as oil and gas, chemical processing, and power generation.

cage type control valve

control valve cage type

What Are The Types Of Balanced Cage Type Control Valve?

- Globe Valve: This type of valve has a spherical body shape and is suitable for applications requiring precise throttling and flow control.

- Angle Valve: Featuring a 90-degree bend in the flow path, angle valves are ideal for installations where space is limited or flow direction needs to be changed.

- Butterfly Valve: Characterized by a disc-shaped closure element, butterfly valves offer quick operation and are often used in large-diameter piping systems.

- Diaphragm Valve: Utilizing a flexible diaphragm as the closure element, diaphragm valves are suitable for handling corrosive or abrasive fluids.

- Ball Valve: Ball valves employ a rotating ball with a bore to control flow. They are known for their tight shutoff capability and minimal pressure drop.

- Plug Valve: Plug valves feature a cylindrical or conical plug that regulates flow by rotating within the valve body.

What Is Balanced Cage Type Control Valve?

The Balanced Cage Type Control Valve is a precision-engineered device designed to regulate the flow of fluids or gases in industrial systems. It incorporates a balanced cage mechanism that ensures consistent performance across varying pressures and flow rates. This type of valve offers superior control accuracy and stability, making it ideal for applications requiring precise flow management in industries such as oil and gas, chemical processing, and power generation.

How to Select the Right Balanced Cage Type Control Valve?

To select the right Balanced Cage Type Control Valve, consider factors like flow requirements, pressure conditions, and fluid properties. Evaluate the valve’s size, material compatibility, and control mechanism to ensure it meets the application’s demands. Additionally, consult with experts like Cameron to determine the best-fit valve for optimal performance and reliability.

Features of Balanced Cage Type Control Valve

- Precision Control: Offers precise regulation of flow rates and pressures, ensuring accurate process control.

- Balanced Cage Design: Incorporates a balanced cage mechanism to maintain stability and reliability across varying operating conditions.

- Versatility: Suitable for a wide range of applications in industries such as oil and gas, chemical processing, and power generation.

- High Performance: Engineered for consistent performance, even in demanding environments with high pressures and temperatures.

- Low Maintenance: Designed for minimal maintenance requirements, reducing downtime and operational costs.

- Durable Construction: Constructed from high-quality materials to withstand corrosive or abrasive fluids and harsh operating conditions.

- Wide Range of Sizes: Available in various sizes to accommodate different flow capacities and piping systems.

- Multiple Control Options: Offers flexibility with pneumatic, electric, or hydraulic control options to suit specific application needs.

Advantages and Disadvantages of Balanced Cage Type Control Valve

Advantages:

- Precise Control: Ensures accurate regulation of flow rates and pressures, enhancing process efficiency.

- Stable Performance: The balanced cage design maintains stability across varying operating conditions, improving reliability.

- Versatility: Suitable for a wide range of applications in diverse industries.

- High Durability: Constructed from robust materials, the valve offers resistance to corrosion and wear, extending service life.

- Low Maintenance: Requires minimal maintenance, reducing downtime and operational costs.

- Flexibility: Available in various sizes and control options to accommodate different system requirements.

- Enhanced Safety: Provides tight shutoff capabilities, contributing to process safety and integrity.

Disadvantages:

- Complex Design: The balanced cage mechanism can make the valve more complex and potentially more expensive compared to simpler valve designs.

- Limited Flow Capacity: May have limitations in handling extremely high flow rates compared to other types of valves.

- Higher Initial Cost: Initial procurement costs may be higher due to the valve’s precision engineering and advanced features.

- Sensitive to Contamination: The valve may be sensitive to fluid contamination, requiring proper filtration and maintenance to prevent issues.

The Specifications of Balanced Cage Type Control Valve

| Specification | Value |

|---|---|

| Type | Balanced Cage Type Control Valve |

| Ball Material | Stainless Steel, Carbon Steel, etc. |

| Attachment Type | Flanged, Threaded, Welded, etc. |

| Thread Standard | ANSI, DIN, JIS, etc. |

| Thread Size | Various sizes available |

| Body Material | Stainless Steel, Carbon Steel, etc. |

| Safe for Use With | Various fluids and gases |

| Handle Type | Lever, Handwheel, Actuator, etc. |

| Handle Material | Stainless Steel, Aluminum, etc. |

| Maximum Working Pressure (psi) | Specific to valve size and model |

| Maximum Working Pressure (bar) | Specific to valve size and model |

| Operating Pressure | Dependent on application |

The Installation Steps for Balanced Cage Type Control Valve

- Preparation: Gather all necessary tools and equipment, including wrenches, gaskets, and sealing compounds.

- Shutdown System: Ensure the system where the valve will be installed is safely shut down and depressurized.

- Positioning: Position the valve in the desired location within the piping system, ensuring proper alignment with the flow direction.

- Attachment: Attach the valve to the pipeline using appropriate attachment methods, such as flanges or threaded connections.

- Tightening: Use calibrated torque wrenches to tighten the bolts or nuts securing the valve in place, following manufacturer specifications.

- Sealing: Apply sealing compounds or gaskets as necessary to ensure leak-tight connections between the valve and pipeline.

- Connection Check: Verify all connections are secure and leak-free before proceeding.

- Testing: Conduct pressure and leak tests according to industry standards and regulations to ensure the valve operates safely and effectively.

- Operational Check: Test the valve’s operation by opening and closing it several times to ensure smooth functioning.

- System Startup: Gradually reintroduce pressure to the system and monitor the valve’s performance during system startup.

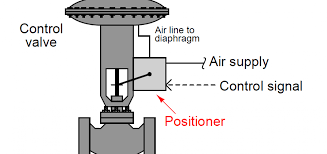

The Operation Theory of Balanced Cage Type Control Valve

- Balanced Cage Design: The valve features a cage-like structure surrounding the plug or ball, which helps to evenly distribute the fluid pressure across the valve’s components.

- Pressure Balance: The balanced cage design ensures that the fluid pressure acting on the valve’s plug or ball is balanced, regardless of variations in inlet or outlet pressure.

- Flow Regulation: When the valve is in operation, adjustments to the position of the plug or ball within the cage control the flow rate of the fluid passing through the valve.

- Precise Control: The balanced cage design allows for precise control of flow rates and pressures, even in high-pressure or high-flow applications.

- Stable Performance: By maintaining pressure balance and evenly distributing forces, the valve operates smoothly and reliably across a range of operating conditions.

- Reduced Noise and Vibration: The balanced cage design helps to minimize noise and vibration associated with fluid flow, resulting in quieter and more stable operation.

- Versatility: Balanced Cage Type Control Valves are suitable for a wide range of applications, including industrial processes, water treatment, HVAC systems, and more.