Non Slam Check Valve

The Application of Non Slam Check Valve

The application of non slam check valves is crucial in preventing water hammer and ensuring smooth flow in piping systems. Non-slam check valves, such as the axial flow non slam check valve, are designed to close without slamming, thus minimizing noise and wear. Various non slam check valve types are available, each suited for specific applications. Cameron, a leading brand in the industry, offers high-quality solutions that enhance system reliability and efficiency.

What Are The Types Of Non Slam Check Valve?

- Axial Flow Non Slam Check Valve: This type ensures a streamlined flow path and minimal pressure drop, making it ideal for high-velocity applications.

- Dual Plate Check Valve: Featuring two spring-loaded plates, this valve closes quickly and smoothly, reducing the risk of water hammer.

- Nozzle Check Valve: This design incorporates a spring-loaded disc that responds to flow changes rapidly, providing excellent non-slam performance.

- Silent Check Valve: Often used in water and wastewater systems, this valve utilizes a spring-assisted closure mechanism to prevent slamming.

- Spring-loaded In-line Check Valve: These valves have a spring mechanism that assists in the smooth closure of the valve, minimizing pressure surges.

What Is Non Slam Check Valve?

A non slam check valve is a type of check valve designed to prevent water hammer by closing smoothly and silently. It features mechanisms like axial flow, dual plates, or spring-loaded designs to ensure that the valve shuts without slamming, thus protecting the system from pressure surges and noise. These valves are essential in applications requiring reliable and quiet operation.

How to Select the Right Non Slam Check Valve?

To select the right non slam check valve, consider factors such as flow rate, pressure conditions, and fluid type. Evaluate the specific non slam check valve types like axial flow non slam check valve or dual plate options, ensuring they match your system’s requirements for minimizing water hammer and maintaining efficiency.

Features of Non Slam Check Valve

- Non-Slam Operation: Designed to close smoothly, preventing water hammer and pressure surges.

- Axial Flow Design: Ensures streamlined flow with minimal pressure drop, enhancing efficiency.

- Quick Closure: Features mechanisms like spring-assisted or dual plate designs for rapid and smooth closing.

- Noise Reduction: Minimizes operational noise, making them ideal for residential and commercial applications.

- Durability: Constructed from robust materials to withstand high pressures and temperatures, ensuring long service life.

- Low Maintenance: Engineered for reliability, requiring minimal upkeep over time.

- Versatility: Available in various non slam check valve types to suit different systems and applications.

- Energy Efficiency: Reduces energy consumption by minimizing flow resistance and maintaining steady flow conditions.

Advantages and Disadvantages of Non Slam Check Valve

Advantages

- Non-Slam Operation: Prevents water hammer and pressure surges, protecting the system.

- Smooth Flow: Axial flow non slam check valve designs ensure minimal pressure drop and efficient flow.

- Quiet Performance: Reduces operational noise, ideal for noise-sensitive environments.

- Durability: Made from high-quality materials, offering long-lasting performance.

- Low Maintenance: Reliable operation with minimal maintenance needs.

- Versatility: Available in various non slam check valve types for different applications and system requirements.

Disadvantages

- Cost: Typically more expensive than standard check valves due to advanced design and materials.

- Complexity: More complex construction can require more expertise for installation and maintenance.

- Limited Availability: Specific types, like axial flow non slam check valves, might not be readily available in all regions.

- Size Constraints: Larger sizes can be bulky and require more space for installation.

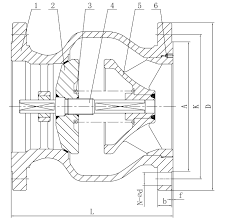

The Specifications of Non Slam Check Valve

| Specification | Details |

|---|---|

| Type | Axial Flow Non Slam Check Valve |

| Ball Material | Stainless Steel |

| Attachment Type | Flanged |

| Thread Standard | ANSI B1.20.1 |

| Thread Size | 2 inches |

| Body Material | Carbon Steel |

| Safe for Use With | Water, Oil, Gas |

| Handle Type | Lever |

| Handle Material | Aluminum |

| Maximum Working Pressure (psi) | 300 psi |

| Maximum Working Pressure (bar) | 20.7 bar |

| Operating Pressure | 50-250 psi |

The Installation Steps for Non Slam Check Valve

- Preparation:

- Ensure the pipeline is clean and free from debris.

- Verify that the valve size matches the pipe diameter.

- Orientation:

- Confirm the flow direction marked on the valve aligns with the system’s flow direction.

- Position the valve horizontally or vertically, depending on the design specifications.

- Flange Connection:

- Align the valve flanges with the pipe flanges.

- Insert appropriate gaskets between flanges to ensure a tight seal.

- Bolting:

- Insert bolts through the flange holes.

- Tighten bolts evenly in a cross-pattern to prevent distortion and ensure a uniform seal.

- Support:

- Provide adequate support for the valve to prevent stress on the pipeline.

- Use pipe supports or hangers as needed.

- Inspection:

- Check for proper alignment and secure bolting.

- Ensure there are no gaps or misalignments in the connection.

- Testing:

- Gradually open the upstream valve to introduce flow.

- Monitor for leaks and ensure the valve operates correctly without slamming.

- Final Adjustment:

- Adjust the valve if necessary to achieve optimal performance.

- Secure all fittings and recheck for any potential issues.

The Operation Theory of Non Slam Check Valve

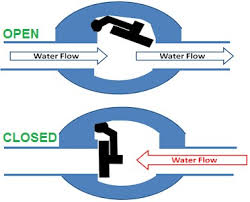

- Forward Flow:

- When the fluid flows in the forward direction, it pushes the valve disc or piston open, allowing fluid to pass through smoothly.

- In an axial flow non slam check valve, the fluid moves in a streamlined path along the valve’s axis, minimizing turbulence and pressure drop.

- Reverse Flow Prevention:

- If the flow direction reverses, the fluid pressure drops, and the valve’s spring mechanism pushes the disc or piston back into the closed position.

- This immediate response prevents the fluid from flowing backward, protecting the system from pressure surges.

- Smooth Closure:

- The spring-loaded mechanism ensures a gradual and controlled closure of the valve, eliminating the sudden stopping of fluid flow.

- This smooth action is critical in non slam check valves, as it reduces the risk of water hammer, which can damage pipes and equipment.

- Axial Flow Mechanism:

- In a non slam axial check valve, the disc or piston moves along the central axis, ensuring a direct and unobstructed flow path.

- This design enhances efficiency by reducing pressure loss and providing a quick response to flow changes.