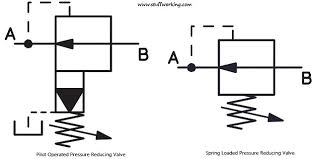

Pressure Reducing Valve Symbol

The Application of Pressure Reducing Valve

The Rotork Pressure Reducing Valve is a critical component designed to regulate fluid pressure effectively. Also known as a high pressure solenoid valve or pressure balanced valve, it ensures optimal performance in various applications. Particularly in steam systems, the steam pressure reducing valve plays a crucial role in maintaining safe and stable pressure levels. Engineered with precision and reliability, Rotork’s Pressure Reducing Valve offers unparalleled control over pressure, safeguarding equipment and processes. Whether in industrial settings or HVAC systems, these valves provide efficient pressure regulation, enhancing system performance and longevity while ensuring safety and efficiency in operation.

symbol of pressure reducing valve

pneumatic pressure relief valve symbol

hydraulic pressure reducing valve symbol

pilot operated pressure reducing valve symbol

pressure reducing valve hydraulic symbol

What Is Pressure Reducing Valve?

A Pressure Reducing Valve is a critical component designed to regulate fluid pressure effectively, ensuring safe and stable pressure levels in various applications.

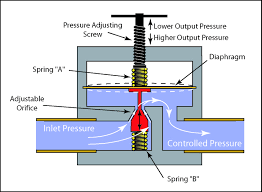

How Does Pressure Reducing Valve work?

A Pressure Reducing Valve operates by sensing the incoming fluid pressure and automatically adjusting to maintain a preset outlet pressure. When the inlet pressure exceeds the set limit, the valve’s mechanism opens to allow flow, then closes as the pressure decreases, ensuring a consistent outlet pressure. This regulation prevents damage to downstream equipment and ensures safe and efficient operation in various applications, such as water distribution systems, steam lines, and hydraulic circuits.

Features of Pressure Reducing Valve

- Pressure Regulation: The primary feature of a Pressure Reducing Valve is its ability to regulate fluid pressure, ensuring it remains within safe and desired limits.

- Automatic Operation: These valves operate automatically, adjusting to changes in inlet pressure to maintain a consistent outlet pressure without manual intervention.

- Versatility: Pressure reducing valves are versatile and can be used in various applications, including water distribution systems, steam lines, and hydraulic circuits.

- Reliability: Engineered for reliability, these valves offer consistent performance over time, ensuring continuous and dependable pressure regulation.

- Protective Function: They protect downstream equipment from damage by preventing excessive pressure from reaching sensitive components.

- Efficiency: By maintaining optimal pressure levels, pressure reducing valves help enhance system efficiency and performance, reducing energy consumption and minimizing waste.

- Compact Design: Many pressure reducing valves feature a compact and space-saving design, making them easy to install and integrate into existing systems.

- Compliance: These valves often comply with industry standards and regulations, providing assurance of adherence to safety guidelines and requirements.

Advantages of Pressure Reducing Valve

- Optimized Pressure: Pressure Reducing Valves ensure fluid pressure remains at optimal levels, preventing damage to downstream equipment.

- Automatic Operation: They operate automatically, adjusting to changes in inlet pressure without manual intervention.

- Versatility: These valves can be used in various applications, including water distribution systems, steam lines, and hydraulic circuits.

- Reliability: Engineered for consistent performance, they provide reliable pressure regulation over time.

- Energy Efficiency: By maintaining optimal pressure levels, pressure reducing valves help minimize energy consumption and reduce operational costs.

- Protection: They safeguard downstream equipment from damage by preventing excessive pressure from reaching sensitive components.

- Safety: Pressure Reducing Valves contribute to system safety by ensuring pressure levels remain within safe limits.

- Ease of Installation: Many models feature a user-friendly design, making installation and integration into existing systems straightforward.

The Specifications of Pressure Reducing Valve

Sure, here’s a specifications table for a Pressure Reducing Valve:

| Specification | Description |

|---|---|

| Type | Pressure Reducing Valve |

| Ball Material | Stainless Steel or Brass |

| Attachment Type | Flanged or Threaded |

| Thread Standard | ANSI, BSPT, NPT, or DIN |

| Thread Size | Typically 1/2 inch to 2 inches |

| Body Material | Brass, Cast Iron, or Stainless Steel |

| Safe for Use With | Water, Steam, Oil, Gas, or Other Fluids |

| Handle Type | Lever, Knob, or Handwheel |

| Handle Material | Aluminum, Stainless Steel, or Plastic |

| Maximum Working Pressure (psi) | Typically up to 300 psi |

| Maximum Working Pressure (bar) | Typically up to 20 bar |

| Operating Pressure | Range: 5-100 psi (0.3-7 bar) or Adjustable |

The Parameter of Pressure Reducing Valve

- Type: Pressure Reducing Valve

- Ball Material: Stainless Steel or Brass

- Attachment Type: Flanged or Threaded

- Thread Standard: ANSI, BSPT, NPT, or DIN

- Thread Size: Typically 1/2 inch to 2 inches

- Body Material: Brass, Cast Iron, or Stainless Steel

- Safe for Use With: Water, Steam, Oil, Gas, or Other Fluids

- Handle Type: Lever, Knob, or Handwheel

- Handle Material: Aluminum, Stainless Steel, or Plastic

- Maximum Working Pressure (psi): Typically up to 300 psi

- Maximum Working Pressure (bar): Typically up to 20 bar

- Operating Pressure: Range: 5-100 psi (0.3-7 bar) or Adjustable

The Operation Theory of Pressure Reducing Valve

The operation theory of a Pressure Reducing Valve involves regulating fluid pressure to a desired level. In steam systems, a **steam pressure relief valve** automatically adjusts to reduce high inlet pressure to a safe outlet pressure, ensuring system integrity. Similarly, in applications requiring both vacuum and pressure regulation, such as vacuum and pressure relief valves, the valve modulates to maintain consistent pressure levels, preventing over-pressurization or vacuum buildup. By sensing changes in inlet pressure, the valve’s mechanism adjusts to restrict flow, stabilizing the outlet pressure within preset limits. This operation ensures safe and efficient performance across various industrial processes, safeguarding equipment and ensuring operational reliability.

The Parameters Table of Pressure Reducing Valve

| Parameter | Description |

|---|---|

| Valve Type | Pressure Reducing Valve |

| Ball Material | Stainless Steel or Brass |

| Attachment Type | Flanged or Threaded |

| Thread Standard | ANSI, BSPT, NPT, or DIN |

| Thread Size | Typically 1/2 inch to 2 inches |

| Body Material | Brass, Cast Iron, or Stainless Steel |

| Safe for Use With | Water, Steam, Oil, Gas, or Other Fluids |

| Handle Type | Lever, Knob, or Handwheel |

| Handle Material | Aluminum, Stainless Steel, or Plastic |

| Maximum Working Pressure (psi) | Typically up to 300 psi |

| Maximum Working Pressure (bar) | Typically up to 20 bar |

| Operating Pressure | Range: 5-100 psi (0.3-7 bar) or Adjustable |