Air Compressor Release Valve

The Application of Air Compressor Release Valve

The Rotork Air Compressor Release Valve is an essential component designed for safety and efficiency in air compressor systems. Also known as an air release valve water main or pneumatic pressure release valve, it functions by automatically releasing excess air or pressure from the system, ensuring optimal performance and preventing damage. Whether in industrial settings or pneumatic applications, such as HVAC systems or air compressors, these valves play a crucial role in maintaining system integrity. Engineered with precision and reliability, Rotork’s Air Compressor Release Valve offers peace of mind, safeguarding equipment and processes from overpressure situations while enhancing operational efficiency.

air compressor air release valve

What Is Air Compressor Release Valve?

An Air Compressor Release Valve is a safety device that automatically releases excess air or pressure from the compressor system to prevent over-pressurization.

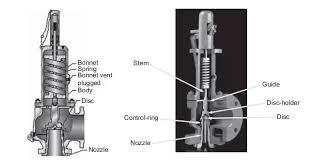

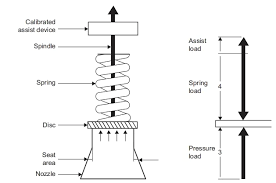

How Does Air Compressor Release Valve work?

An Air Compressor Release Valve operates by sensing the pressure within the compressor system. When pressure exceeds a preset limit, the valve automatically opens, allowing excess air to escape, thereby reducing pressure to safe levels and preventing damage to the compressor and associated equipment.

Features of Air Compressor Release Valve

- Safety: The primary feature of an Air Compressor Release Valve is its role in maintaining system safety by preventing over-pressurization.

- Automatic Operation: These valves operate automatically, opening when pressure exceeds safe levels without the need for manual intervention.

- Efficiency: By releasing excess air or pressure, they help optimize compressor performance, ensuring efficient operation.

- Versatility: Air compressor release valves are compatible with various compressor systems, making them suitable for different applications.

- Reliability: Engineered for reliability, these valves offer consistent performance over time, ensuring continuous protection against overpressure events.

- Quick Response: They have rapid response times, opening swiftly to release pressure when necessary, minimizing the risk of equipment damage.

- Ease of Installation: Designed for easy installation, air compressor release valves can be integrated into existing systems with minimal effort.

- Compliance: Many release valves comply with industry standards and regulations for safety, providing assurance of adherence to relevant guidelines.

Advantages of Air Compressor Release Valve

- Pressure Regulation: Air compressor release valves enable precise regulation of air pressure within the system, preventing it from exceeding safe levels.

- Equipment Protection: By releasing excess air or pressure, these valves protect the compressor and associated equipment from damage or failure due to over-pressurization.

- Safety Assurance: They ensure operational safety by preventing hazardous situations that could arise from excessive pressure buildup.

- Automatic Operation: Release valves operate automatically, requiring no manual intervention, which enhances system efficiency and reliability.

- Cost Savings: By preventing damage to equipment, air compressor release valves help avoid costly repairs or replacements, leading to long-term cost savings.

- Versatility: These valves are compatible with various types of air compressor systems, offering versatility in application.

- Compliance: Many release valves comply with industry standards and regulations for safety, providing assurance of adherence to relevant guidelines.

- Reliable Performance: Engineered for reliability, air compressor release valves offer consistent performance over time, ensuring continuous protection against overpressure events.

The Specifications of Air Compressor Release Valve

| Specification | Description |

|---|---|

| Type | Air Compressor Release Valve |

| Ball Material | Stainless Steel |

| Attachment Type | Flanged / Threaded |

| Thread Standard | NPT / BSP |

| Thread Size | 1/2 inch / 3/4 inch |

| Body Material | Brass / Aluminum |

| Safe for Use With | Compressed Air / Specific Fluid |

| Handle Type | Lever / Knob |

| Handle Material | Plastic / Aluminum |

| Maximum Working Pressure | 150 psi / 10 bar |

| Operating Pressure | 50-100 psi |

The Parameter of Air Compressor Release Valve

- Type: Air Compressor Release Valve

- Ball Material: Stainless Steel

- Attachment Type: Flanged / Threaded

- Thread Standard: NPT / BSP

- Thread Size: 1/2 inch / 3/4 inch

- Body Material: Brass / Aluminum

- Safe for Use With: Compressed Air / Specific Fluid

- Handle Type: Lever / Knob

- Handle Material: Plastic / Aluminum

- Maximum Working Pressure: 150 psi / 10 bar

- Operating Pressure: 50-100 psi

The Operation Theory of Air Compressor Release Valve

The operation theory of an Air Compressor Release Valve, also known as an air pressure release valve or vacuum pressure release valve, involves maintaining system pressure within safe limits. When pressure surpasses the preset threshold, the valve automatically opens to release excess air or vacuum pressure, preventing over-pressurization or vacuum build-up. This action safeguards the compressor and associated equipment from damage and ensures efficient and safe operation. Whether in pneumatic systems or vacuum applications, these valves play a crucial role in maintaining system integrity and preventing potential hazards.

The Parameters Table of Air Compressor Release Valve

| Parameter | Description |

|---|---|

| Valve Type | Air Compressor Release Valve |

| Ball Material | Stainless Steel |

| Attachment Type | Flanged / Threaded |

| Thread Standard | NPT / BSP |

| Thread Size | 1/2 inch / 3/4 inch |

| Body Material | Brass / Aluminum |

| Safe for Use With | Compressed Air / Specific Fluid |

| Handle Type | Lever / Knob |

| Handle Material | Plastic / Aluminum |

| Maximum Working Pressure | 150 psi / 10 bar |

| Operating Pressure | 50-100 psi |