Triple Offset Butterfly Valve

The Application of Triple Offset Butterfly Valve

The Triple Offset Butterfly Valve, also known as the triple offset valve butterfly, is a specialized valve design that offers exceptional performance and versatility. Manufactured by renowned brands like Cameron, these valves feature a unique triple offset geometry, which provides superior sealing capabilities and extended service life. The Vanessa Triple Offset Butterfly Valve is a prime example of this advanced technology, widely utilized in high-pressure, high-temperature, and corrosive applications across various industries, including oil and gas, petrochemical, and power generation. The triple offset design minimizes wear and tear, ensuring reliable and efficient flow control even in the most demanding environments. With their unparalleled performance and durability, Triple Offset Butterfly Valves have become the preferred choice for mission-critical applications where safety, precision, and long-term operability are of utmost importance.

What Are The Types Of Triple Offset Butterfly Valve?

- Wafer-Style Triple Offset Butterfly Valve:

- This type fits between two pipeline flanges and is secured in place by the flange bolts.

- Wafer-style valves are compact and economical, making them suitable for space-constrained installations.

- Lug-Style Triple Offset Butterfly Valve:

- The lug-style valve has protruding bolt holes, allowing it to be installed independently and then connected to the pipeline.

- Lug-style valves provide additional support and can be used as an end-of-line valve.

- Double Flanged Triple Offset Butterfly Valve:

- This type has flanges on both ends, enabling it to be installed as a standalone component in the pipeline.

- Double flanged valves offer increased stability and ease of maintenance.

- High-Performance Triple Offset Butterfly Valve:

- These advanced valves feature enhanced sealing mechanisms and materials to withstand high pressures, temperatures, and demanding operating conditions.

- High-performance triple offset valves are often used in critical applications where reliability and efficiency are paramount.

- Cryogenic Triple Offset Butterfly Valve:

- Specially designed for low-temperature applications, these valves incorporate materials and seals suitable for cryogenic environments.

- Cryogenic triple offset valves are essential in industries like LNG, petrochemical, and natural gas processing.

What Is Triple Offset Butterfly Valve?

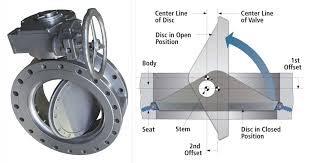

A Triple Offset Butterfly Valve is a specialized type of industrial valve that utilizes a unique three-dimensional offset design to achieve superior sealing performance and extended service life. Unlike traditional butterfly valves, which rely on a single offset axis, the triple offset design incorporates an additional two offsets, resulting in a more complex yet highly effective sealing mechanism. This advanced configuration allows the valve disc to create a tighter, more consistent seal against the valve seat, even under high-pressure and high-temperature conditions. The triple offset geometry also minimizes wear and tear, enabling these valves to maintain their integrity and reliability for extended periods, making them a preferred choice for critical applications in industries such as oil and gas, petrochemicals, and power generation.

How to Select the Right Triple Offset Butterfly Valve?

Line Size: Ensure the valve size matches the pipeline diameter to ensure proper fit and sealing performance.

Pressure Rating: Choose a valve with a pressure rating that exceeds the maximum expected system pressure to maintain safety and reliability.

Temperature Range: Verify the valve materials and seals can withstand the operating temperatures, whether at high or cryogenic levels.

Fluid Compatibility: Select a valve with materials compatible with the media being controlled to prevent corrosion or chemical attack.

Actuation Type: Determine the required actuation method, such as manual, electric, or pneumatic, based on the application’s control requirements.

Certifications: Opt for valves that meet industry standards and certifications for the intended use, ensuring compliance with safety regulations.

By carefully evaluating these key factors, you can select the Triple Offset Butterfly Valve that best suits the specific needs of your application, ensuring optimal performance, efficiency, and longevity.

Features of Triple Offset Butterfly Valve

Sealing Mechanism:

The unique triple offset design of the valve creates a tighter, more consistent seal against the valve seat, ensuring robust isolation even under high-pressure and high-temperature conditions.

Reduced Wear and Tear:

The complex geometry minimizes friction and contact between the disc and seat, leading to extended service life and reduced maintenance requirements.

Improved Flow Control:

The precise disc positioning and sealing capabilities enable accurate flow regulation and throttling, making the valve suitable for demanding control applications.

Compact Design:

The streamlined profile of the Triple Offset Butterfly Valve allows for easy installation in space-constrained environments.

Material Versatility:

These valves are available in a wide range of materials, including stainless steel, exotic alloys, and even cryogenic-grade components, to suit diverse operating conditions.

Bi-Directional Sealing:

The valve can provide reliable sealing in both the forward and reverse flow directions, enhancing its versatility and flexibility.

Severe Service Capability:

The robust design and advanced materials make Triple Offset Butterfly Valves well-suited for use in harsh, high-pressure, and high-temperature applications.

Advantages and Disadvantages of Triple Offset Butterfly Valve

Improved Sealing: The unique triple offset design creates a tighter, more consistent seal, ensuring reliable isolation even in high-pressure and high-temperature applications.

Extended Service Life: The reduced wear and tear on the valve components leads to a longer service life, minimizing the need for frequent maintenance and replacement.

Versatile Flow Control: The precise disc positioning and sealing capabilities allow for accurate flow regulation and throttling, making the valve suitable for demanding control applications.

Compact and Space-Efficient: The streamlined profile of the triple offset butterfly valve allows for easy installation in space-constrained environments.

Material Compatibility: These valves are available in a wide range of materials, including stainless steel, exotic alloys, and cryogenic-grade components, to suit diverse operating conditions.

Bi-Directional Sealing: The valve can provide reliable sealing in both the forward and reverse flow directions, enhancing its versatility and flexibility.

Severe Service Capability: The robust design and advanced materials make triple offset butterfly valves well-suited for use in harsh, high-pressure, and high-temperature applications.

Disadvantages of Triple Offset Butterfly Valve:

Higher Cost: The complex design and specialized manufacturing process of triple offset butterfly valves typically result in a higher initial cost compared to traditional butterfly valves.

Increased Maintenance Complexity: The intricate geometry and tight tolerances of the valve may require more specialized maintenance and repair procedures, which can be more time-consuming and costly.

Limited Size Range: Triple offset butterfly valves are generally available in a more limited size range compared to other valve types, which may limit their applicability in certain applications.

The Specifications of Triple Offset Butterfly Valve

| Specification | Details |

|---|---|

| Type | Triple Offset Butterfly Valve |

| Ball Material | 316 Stainless Steel |

| Attachment Type | Wafer-Style |

| Thread Standard | ANSI 150 |

| Thread Size | 2 inches |

| Body Material | 316 Stainless Steel |

| Safe for Use With | Water, Oil, Gas, Steam |

| Handle Type | Lever Handle |

| Handle Material | Aluminum |

| Maximum Working Pressure (psi) | 285 psi |

| Maximum Working Pressure (bar) | 19.7 bar |

| Operating Pressure | 0-19.7 bar |

The Installation Steps for Triple Offset Butterfly Valve

1. Verify Valve and Pipe Dimensions: Ensure the valve size matches the pipeline diameter to guarantee proper fit and sealing performance.

2. Clean the Pipe and Mounting Surfaces: Thoroughly clean the pipe interior and valve mounting surfaces, removing any debris or contaminants to ensure a clean installation.

3. Position the Valve: Place the valve between the pipe flanges, aligning the bolt holes and ensuring the valve centerline is concentric with the pipe centerline.

4. Connect the Flanges: Use high-strength bolts to secure the valve to the pipe flanges, tightening the bolts in a diagonal pattern to ensure a tight, leak-free seal.

5. Attach the Actuator: Connect the required electric, pneumatic, or manual actuator to the valve stem, ensuring proper installation and calibration.

6. Perform Slow Open/Close Testing: Operate the valve slowly, checking for smooth and unrestricted movement, as well as proper sealing performance.

7. Conduct Final Inspection: Verify that all connections are tight and leak-free, and that the actuator is functioning correctly, ensuring the entire installation meets requirements.

8. Place into Service: After confirming everything is operating as expected, carefully put the valve into normal service, monitoring its performance closely.

The Operation Theory of Triple Offset Butterfly Valve

The triple offset butterfly valve’s unique design and operating principle set it apart from traditional butterfly valves. The key aspects of its operation theory are:

- Offset Shaft Alignment: The valve’s shaft is positioned in a triple offset arrangement, meaning it is displaced from the valve’s center in three dimensions – radially, laterally, and longitudinally. This offset alignment reduces friction and wear between the disc and seat.

- Sealing Mechanism: The complex geometry of the valve disc and seat creates a tight, metal-to-metal seal when the valve is closed. This seal is maintained even under high pressure and temperature conditions, providing reliable isolation.

- Precise Flow Control: The exact positioning of the disc enables accurate flow regulation and throttling, making the valve suitable for demanding control applications.

Triple Offset Butterfly Valve Manufacturers:

- ABZ Valve: ABZ is a leading manufacturer of triple offset butterfly valves, offering a wide range of sizes, materials, and specialty designs for various industries.

- Velan: Velan is a global provider of high-performance triple offset butterfly valves, known for their quality, reliability, and innovative features.

- Emerson: Emerson’s triple offset butterfly valve line, including the Dantorque brand, is widely recognized for its robust construction and advanced sealing technology.

- Bray Controls: Bray is a prominent manufacturer of triple offset butterfly valves, with a focus on delivering reliable and efficient flow control solutions.

- DeZURIK: DeZURIK is a respected producer of high-quality triple offset butterfly valves, known for their exceptional performance in demanding applications.