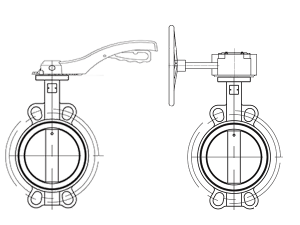

Wafer Butterfly Valve

The Application of Wafer Butterfly Valve

The Wafer Butterfly Valve, a product of Cameron, is a versatile and efficient solution for fluid control applications. Unlike traditional lug vs wafer butterfly valves, the wafer design offers a compact and lightweight construction, making it ideal for space-constrained installations. Its unique design also allows for easy installation between flanges without the need for additional flange gaskets. Engineers and operators can choose between wafer vs lug butterfly valves based on their specific requirements, ensuring optimal performance in various applications. Widely recognized in process industries, the Wafer Butterfly Valve features a distinctive P&ID butterfly valve symbol and is compliant with industry standards like Trim 12 material. Trust the reliability and performance of Cameron gate valve butterfly valve solutions for your fluid control needs.

Features of Wafer Butterfly Valve

The Wafer Butterfly Valve is:

- Simple and compact, easy to assemble and repair

- Lightweight, with small operation torque for easy opening and closing

- Offers minimal flow resistance, leading to energy savings

- Features reliable sealing, ensuring zero leakage and a long service life

The Parameter of Wafer Butterfly Valve

- Valve Type: Wafer Butterfly Valve

- Brand: Cameron (optional)

- Design: Wafer-style design, compact and lightweight

- Size Range: Available in various sizes to fit different pipe diameters

- Material: Constructed from materials such as carbon steel, stainless steel, or ductile iron

- Operation: Manual or automated operation options available

- Sealing: Utilizes resilient seat or metal-to-metal sealing for reliable performance

- Pressure Rating: Suitable for low to medium pressure applications

- Temperature Range: Designed to operate within specific temperature limits

- End Connections: Typically designed for flange connections, compatible with ANSI, DIN, or other standards

The Operation Theory of Wafer Butterfly Valve

The operation theory of the Wafer Butterfly Valve is straightforward and efficient. Similar to a PVC butterfly valve or other sizes like 10 butterfly valve and 12 butterfly valve, it relies on a disc (or “butterfly”) mounted on a central shaft to control the flow of fluid. When the valve is open, the disc rotates parallel to the flow direction, allowing fluid to pass through. Conversely, when closed, the disc rotates perpendicular to the flow direction, blocking the flow. The valve may feature a resilient or metal seated design for enhanced sealing performance, ensuring reliable operation in various applications.

The Parameters Table of Wafer Butterfly Valve

| Component | Material |

|---|---|

| Body | Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel, PVC, CPVC, etc. |

| Disc | Ductile Iron, Stainless Steel, Aluminum Bronze, PVC, CPVC, etc. |

| Seat | EPDM, NBR, Viton, PTFE, Metal (e.g., Stainless Steel) |

| Stem | Stainless Steel, Carbon Steel, Monel, etc. |

| Stem Seal | EPDM, PTFE, Viton, NBR, etc. |

| Body Seal | EPDM, NBR, Viton, PTFE, etc. |

| Bolts and Nuts | Stainless Steel, Carbon Steel, Alloy Steel, etc. |

Relevant Information about Wafer Butterfly Valve

- Rotor (Rator): In a butterfly valve, the disc or “butterfly” acts as the closure element. It rotates within the valve body to control the flow of fluid.

- Stator: The stator is not typically a component of a butterfly valve. It’s commonly found in motors or generators and serves to provide a stationary magnetic field.

- Universal Joint: Universal joints are not typically found in butterfly valves. They are commonly used in mechanical systems to transmit torque between non-aligned shafts.

- Shaft Seal: Butterfly valves may have a shaft seal to prevent leakage along the valve stem. This seal can be made of materials like elastomers or PTFE.

- Driving System: In manual butterfly valves, the driving system involves a handle or lever that the operator uses to manually open or close the valve. In automated valves, a driving system such as an electric, pneumatic, or hydraulic actuator is used to control the valve remotely.

If you’re looking for specific information about these components in relation to a valve, it’s important to consult the manufacturer’s documentation or specifications for the particular valve model you’re interested in.