What are Plastic Valves and Their Advantages

The Application of Plastic Valves

The use of plastic shut off valves, plastic ball valves, and plastic valve covers has become increasingly prevalent across various industries. These versatile components offer numerous advantages, including corrosion resistance, lightweight design, and cost-effectiveness. Cameron, a renowned manufacturer, has been at the forefront of this trend, providing high-quality plastic valve solutions tailored to meet the specific needs of its clients. Whether it’s managing fluid flow or ensuring reliable shut-off capabilities, the application of plastic valves has become an integral part of modern industrial and commercial operations, demonstrating their versatility and durability in a wide range of applications.

sluice gate valve

What Are The Types Of Plastic Valves?

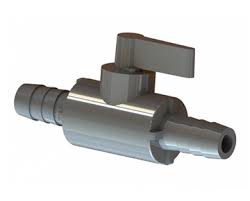

Plastic Ball Valves: These valves feature a spherical ball with a bore that can be rotated to control the flow of fluids. They are known for their reliable on/off performance, easy operation, and suitability for a variety of media, making them a popular choice across many industries.

Plastic Butterfly Valves: Designed with a rotary disk that pivots to open and close the valve, plastic butterfly valves offer a compact and cost-effective solution for flow control. They are often used in applications with limited space and where quick shut-off is required.

Plastic Gate Valves: Featuring a sliding gate or wedge that rises to open the valve and seals against the body to close it, plastic gate valves are well-suited for applications requiring positive shut-off and minimal pressure drop.

Plastic Globe Valves: These valves use a movable disk or plug that seats against a fixed ring or cage to control flow. Plastic globe valves are commonly used for throttling or regulating applications, providing precise control over fluid flow.

Plastic Check Valves: Designed to allow fluid flow in only one direction, plastic check valves prevent backflow and are often used in pumping systems, pipelines, and other applications where unidirectional flow is critical.

What Is Plastic Valves?

Plastic valves are a class of valves that utilize plastic materials, such as polyvinyl chloride (PVC), polypropylene (PP), or polytetrafluoroethylene (PTFE), instead of traditional metal components. These valves are designed to provide flow control and shut-off capabilities in various industrial, commercial, and residential applications. Plastic valves offer several advantages over their metal counterparts, including corrosion resistance, lightweight construction, and cost-effectiveness. They are widely used in industries like water treatment, chemical processing, food and beverage, and HVAC systems, where their unique properties make them well-suited for handling a wide range of fluids and operating conditions. The versatility and durability of plastic valves have contributed to their growing popularity and widespread adoption across numerous sectors.

How to Select the Right Plastic Valves?

Media Compatibility: Choose plastic materials that are compatible with the specific fluids, gases, or chemicals that will be flowing through the valve. This ensures the valve’s integrity and longevity in the intended environment.

Pressure and Temperature Ratings: Assess the operating pressure and temperature range of the application and select plastic valves with appropriate ratings to withstand the required conditions.

Size and Flow Characteristics: Determine the necessary valve size and flow capacity based on the system’s requirements to ensure optimal performance and avoid restrictions or pressure drops.

Installation and Accessibility: Consider the physical constraints of the installation location and select plastic valves that are easy to access and maintain for routine inspection and servicing.

Features of Plastic Valves

Corrosion Resistance:

Plastic valves are highly resistant to corrosion, making them suitable for a wide range of environments and media, including aggressive chemicals, saltwater, and other corrosive substances.

Lightweight Design:

The use of plastic materials results in a lightweight construction, reducing the overall weight of the valve and simplifying installation, handling, and transportation.

Cost-Effectiveness:

Compared to traditional metal valves, plastic valves are generally more cost-effective, making them a practical choice for budget-conscious applications.

Chemical Compatibility:

The chemical inertness of certain plastic materials, such as PTFE, allows plastic valves to handle a diverse range of chemicals without compromising their integrity.

Thermal Insulation:

Plastic valves can provide improved thermal insulation properties, which can be beneficial in applications where temperature control is crucial.

Reduced Maintenance:

The inherent durability and resistance to wear and tear of plastic valves can lead to reduced maintenance requirements and extended service life.

Advantages and Disadvantages of Plastic Valves

Advantages of Plastic Valves:

Corrosion Resistance: Plastic valves are highly resistant to corrosion, making them suitable for a wide range of harsh environments and aggressive media.

Lightweight Design: The use of plastic materials results in a lightweight construction, simplifying installation and handling.

Cost-Effectiveness: Compared to traditional metal valves, plastic valves are generally more cost-effective, making them a practical choice for budget-conscious applications.

Chemical Compatibility: The chemical inertness of certain plastic materials allows plastic valves to handle a diverse range of chemicals without compromising their integrity.

Reduced Maintenance: The inherent durability and resistance to wear and tear of plastic valves can lead to reduced maintenance requirements and extended service life.

Disadvantages of Plastic Valves:

Limited Pressure and Temperature Ratings: Plastic valves may have lower pressure and temperature ratings compared to metal valves, restricting their use in high-pressure or high-temperature applications.

Potential for Brittleness: Depending on the plastic material, plastic valves may be more susceptible to brittleness and potential cracking, especially in extreme environments or under severe stress.

Reduced Structural Integrity: Plastic valves may not possess the same level of structural integrity as metal valves, potentially leading to deformation or failure under high loads or stress.

Difficulty in Repairing: Repairing or modifying plastic valves can be more challenging compared to metal valves, as specialized tools and techniques may be required.

Limited Flow Capacity: In certain applications, plastic valves may have a lower flow capacity compared to their metal counterparts, which can be a limiting factor in some systems.

The Specifications of Plastic Valves

| Specification | Details |

|---|---|

| Type | Plastic Ball Valve |

| Ball Material | Polytetrafluoroethylene (PTFE) |

| Attachment Type | Threaded |

| Thread Standard | NPT |

| Thread Size | 1/2 inch |

| Body Material | Polypropylene (PP) |

| Safe for Use With | Water, Acids, Oils, Solvents, Gases |

| Handle Type | Lever |

| Handle Material | Polypropylene (PP) |

| Maximum Working Pressure (psi) | 150 |

| Maximum Working Pressure (bar) | 10 |

| Operating Pressure | 0-150 psi (0-10 bar) |

The Installation Steps for Plastic Valves

Step 1: Prepare the Pipe

- Ensure the pipe is clean, free of burrs, and the correct size for the valve.

- Cut the pipe to the appropriate length, leaving enough space for the valve installation.

Step 2: Apply Thread Sealant (for Threaded Valves)

- Apply a suitable thread sealant, such as PTFE tape or pipe dope, to the valve’s threaded ends.

- This will help create a tight, leak-proof seal.

Step 3: Install the Valve

- Carefully thread the valve into the pipe, ensuring it is aligned properly.

- Use a wrench or pliers to tighten the valve, taking care not to overtighten.

Step 4: Check for Leaks

- Turn on the system and check for any leaks around the valve connections.

- If leaks are present, tighten the valve further or apply additional sealant.

Step 5: Operate the Valve

- Ensure the valve is in the fully open or closed position, depending on the application.

- Test the valve’s operation by opening and closing it several times.

Step 6: Insulate the Valve (if Necessary)

- For applications requiring temperature control, consider insulating the valve to maintain the desired temperature.

Step 7: Secure the Valve (if Necessary)

- In some cases, additional support or bracing may be required to prevent movement or stress on the valve.

The Operation Theory of Plastic Valves

1/2 inch PEX Shut Off Valve:

The 1/2 inch PEX shut off valve operates based on a simple on/off mechanism. When the valve is in the open position, fluid can freely flow through the valve. When the valve is in the closed position, a internal seal blocks the flow, allowing the valve to shut off the line. This type of valve is commonly used to isolate sections of a PEX plumbing system for maintenance or repairs.

The valve’s operation is controlled by turning the handle. When the handle is in the vertical position, the valve is open, and when the handle is in the horizontal position, the valve is closed. The valve’s internal components, made of plastic materials, provide a tight seal when closed to prevent any leakage.

1 1/2 inch Plastic Ball Valve:

The 1 1/2 inch plastic ball valve operates on the principle of a rotating ball mechanism. The ball, also made of plastic, has a bore running through the center. When the valve is in the open position, the bore is aligned with the pipe, allowing fluid to flow freely. When the valve is in the closed position, the ball rotates to block the flow, effectively shutting off the line.

The valve is operated by turning the handle, which is connected to the ball. A quarter-turn (90 degrees) of the handle is typically sufficient to fully open or close the valve. The plastic ball and seals provide a tight seal when the valve is closed, preventing any leaks or unwanted fluid flow.

Both the PEX shut off valve and the plastic ball valve offer the advantages of corrosion resistance, lightweight construction, and cost-effectiveness that are inherent in plastic valve designs. Their simple yet effective operation makes them suitable for a variety of applications, from plumbing and HVAC systems to industrial process lines.