Gas Pressure Regulator Valve

The Application of Gas Pressure Regulator Valve

Introducing the Rotork Gas Pressure Regulator Valve, a crucial component for managing gas pressure in various applications. As a specialized gas pressure valve, it ensures precise control over gas flow, maintaining optimal pressure levels. Designed to safeguard against pressure surges, it functions akin to a gas pressure relief valve, offering safety and efficiency. Whether in industrial, commercial, or residential settings, gas control valves like Rotork’s provide reliable regulation, ensuring smooth operation and preventing damage to downstream equipment. With its robust design and advanced features, Rotork Gas Pressure Regulator Valve stands as a trusted solution for gas pressure management needs.

What Is Gas Pressure Regulator Valve?

A Gas Pressure Regulator Valve is a device designed to control and regulate the pressure of gas within a system. It ensures that the gas pressure remains within a specified range, regardless of fluctuations in upstream pressure. By adjusting the valve, users can maintain consistent gas flow rates, prevent over-pressurization, and safeguard downstream equipment. Gas Pressure Regulator Valves are essential in various industries, including oil and gas, manufacturing, and utilities, where precise control of gas pressure is critical for safety and operational efficiency.

How Does Gas Pressure Regulator Valve work?

The Gas Pressure Regulator Valve works by sensing the upstream pressure of the gas and adjusting the valve’s opening accordingly to maintain a consistent downstream pressure. When the upstream pressure exceeds the desired level, the regulator restricts the flow by partially closing the valve, reducing the pressure downstream. Conversely, if the upstream pressure drops below the set point, the regulator opens the valve wider to allow more gas flow and maintain the desired pressure. This continuous adjustment ensures stable gas pressure within the system, ensuring safe and efficient operation.

Features of Gas Pressure Regulator Valve

- Precise Regulation: Gas Pressure Regulator Valves offer precise control over gas pressure levels, ensuring consistency in flow rates.

- Safety Features: Equipped with safety mechanisms such as over-pressure protection and pressure relief valves to prevent accidents.

- Versatility: Suitable for a wide range of gases, including natural gas, propane, and industrial gases, making them versatile in various applications.

- Durable Construction: Constructed from high-quality materials like stainless steel or brass, ensuring durability and resistance to corrosion.

- Compact Design: Compact and space-saving design makes installation easy and suitable for restricted spaces.

- Adjustability: Some models feature adjustable settings for precise customization according to specific pressure requirements.

- Compatibility: Compatible with different types of gas systems and pipelines, enhancing flexibility in installation and usage.

- Efficiency: Designed for efficient operation, minimizing energy consumption and maximizing performance.

Advantages of Gas Pressure Regulator Valve

- Stable Pressure: Gas Pressure Regulator Valves ensure stable pressure within gas systems, preventing pressure fluctuations that could disrupt operations.

- Safety: They incorporate safety features such as pressure relief valves to protect equipment and personnel from over-pressurization hazards.

- Versatility: Suitable for a wide range of gases and applications, providing versatility and adaptability in various industries.

- Precise Control: Offering precise control over gas pressure levels, allowing for efficient and accurate regulation to meet specific requirements.

- Cost-Effectiveness: By maintaining consistent pressure levels, they help optimize gas usage and reduce operational costs over time.

- Reliability: Known for their reliability and durability, ensuring long-term performance and minimal downtime.

- Ease of Installation: Designed for easy installation and integration into existing gas systems, minimizing setup time and complexity.

- Energy Efficiency: By regulating gas flow effectively, they contribute to energy efficiency and environmental sustainability.

The Specifications of Gas Pressure Regulator Valve

| Specification | Gas Pressure Regulator Valve |

|---|---|

| Type | Pressure Regulator Valve |

| Ball Material | N/A |

| Attachment Type | Flanged, Threaded, Welded |

| Thread Standard | ANSI, BSPT, NPT, DIN, JIS |

| Thread Size | Typically 1/2 inch to 12 inches |

| Body Material | Stainless Steel, Brass, or Aluminum |

| Safe for Use With | Natural Gas, Propane, Industrial Gases |

| Handle Type | Handwheel, Lever, or Actuator |

| Handle Material | Cast Iron, Stainless Steel, or Aluminum |

| Maximum Working Pressure | Up to 500 psi (34.5 bar) |

| Operating Pressure | Range: 5-200 psi (0.3-14 bar) |

The Parameter of Gas Pressure Regulator Valve

- Type: Gas Pressure Regulator Valves are categorized as pressure regulator valves, designed specifically to regulate and control the pressure of gases within systems.

- Attachment Type: They are available in various attachment types such as flanged, threaded, or welded, allowing for flexible installation options depending on system requirements.

- Thread Standard: Gas Pressure Regulator Valves conform to industry-standard thread standards such as ANSI, BSPT, NPT, DIN, or JIS, ensuring compatibility with a wide range of fittings and connectors.

- Thread Size: Typically, these valves come in sizes ranging from 1/2 inch to 12 inches, catering to different pipeline diameters and flow rates.

- Body Material: Gas Pressure Regulator Valves are constructed from high-quality materials such as stainless steel, brass, or aluminum, ensuring durability and resistance to corrosion.

- Safe for Use With: They are suitable for use with various gases including natural gas, propane, and industrial gases, providing versatility in application.

- Handle Type: These valves feature different handle types such as handwheels, levers, or actuators for manual or automated operation, offering flexibility in control.

- Handle Material: The handles of Gas Pressure Regulator Valves are typically made of materials like cast iron, stainless steel, or aluminum, ensuring ease of operation and durability.

- Maximum Working Pressure: They can handle maximum working pressures of up to 500 psi (34.5 bar), depending on the specific model and application requirements.

- Operating Pressure: Gas Pressure Regulator Valves operate within a range of 5-200 psi (0.3-14 bar), providing precise control over gas pressure levels to meet specific system needs.

The Operation Theory of Gas Pressure Regulator Valve

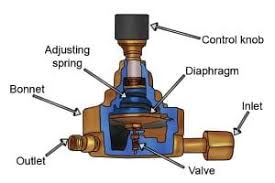

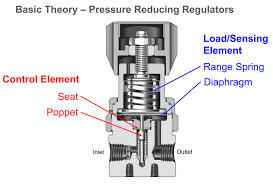

- Pressure Sensing: Gas Pressure Regulator Valves utilize a diaphragm or piston mechanism to sense the upstream pressure of the gas. This sensing element detects changes in pressure and translates them into mechanical motion.

- Adjustment Mechanism: Upon sensing changes in pressure, the valve’s adjustment mechanism, often a spring-loaded device, responds accordingly. If the upstream pressure exceeds the desired set point, the adjustment mechanism compresses the spring, causing the valve to close partially, thereby reducing the flow of gas.

- Gas Flow Regulation: As the valve closes, it restricts the flow of gas, creating a backpressure that counteracts the incoming pressure. Conversely, if the upstream pressure drops below the set point, the adjustment mechanism decompresses the spring, allowing the valve to open further and increase the flow of gas to maintain the desired pressure.

- Precision Control: Gas Pressure Regulator Valves provide precise control over gas pressure levels, ensuring stability and consistency in the downstream system. This control is essential for maintaining safe and efficient operation, particularly in applications where precise pressure regulation is critical.

The Parameters Table of Gas Pressure Regulator Valve

| Parameter | Gas Pressure Regulator Valve |

|---|---|

| Type | Pressure Regulator Valve |

| Body Material | Stainless Steel, Brass, Aluminum |

| Attachment Type | Flanged, Threaded, Welded |

| Thread Standard | ANSI, BSPT, NPT, DIN, JIS |

| Thread Size | Typically 1/2 inch to 12 inches |

| Safe for Use With | Natural Gas, Propane, Industrial Gases |

| Maximum Working Pressure | Up to 500 psi (34.5 bar) |

| Operating Pressure | Range: 5-200 psi (0.3-14 bar) |