Cooling Tower Valves Company

The Application of Cooling Tower Valves

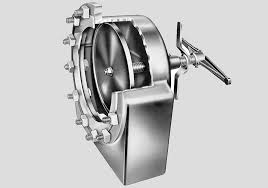

Introducing Flowserve Cooling Tower Valves, engineered for optimal performance in cooling tower systems. These valves are designed to address various challenges in cooling tower operations, offering reliability and efficiency. Equipped with innovative features like cool valve stem caps to prevent heat buildup, cooling tower float valves for precise water level control, and EGR cooler bypass valves for enhanced system efficiency. Flowserve Cooling Tower Valves ensure smooth operation, minimize downtime, and maximize cooling tower performance, making them indispensable components in cooling systems across industries.

plug valve vs ball valve

pressure reducing valve symbol

ball valve vs butterfly valve

valve bonnets

What Is Cooling Tower Valves?

Cooling Tower Valves are specialized components designed for regulating fluid flow within cooling tower systems. These valves play a crucial role in controlling the flow of water, chemicals, or other fluids to maintain optimal operating conditions. Equipped with features such as precise control mechanisms and durable construction, cooling tower valves ensure efficient cooling tower performance by regulating flow rates, managing water levels, and enhancing system reliability. They are essential for maintaining proper operation and maximizing the efficiency of cooling tower systems across various industrial applications.

How Does Cooling Tower Valves work?

Cooling Tower Valves regulate fluid flow within cooling tower systems by controlling the opening and closing of the valve mechanism. When the valve is open, fluid is allowed to pass through, while closing the valve restricts or stops the flow. This action is facilitated by precision-engineered components such as valve stems, discs, or balls, which are operated manually or automatically depending on the valve type. Cooling tower valves play a vital role in maintaining proper fluid levels, controlling temperature, and optimizing system performance in cooling tower applications.

Features of Cooling Tower Valves

- Precision Control: Cooling tower valves offer precise control over fluid flow rates, allowing for accurate adjustments to meet specific system requirements.

- Durable Construction: Built with high-quality materials, these valves withstand harsh environmental conditions, ensuring long-term reliability and performance.

- Corrosion Resistance: Featuring corrosion-resistant coatings or materials, cooling tower valves maintain their integrity and functionality even in corrosive environments.

- Versatile Applications: Designed to accommodate various fluids and temperatures, these valves are suitable for a wide range of cooling tower systems and industrial processes.

- Efficient Operation: With smooth valve action and minimal friction, cooling tower valves operate efficiently, minimizing energy consumption and maximizing system efficiency.

- Easy Maintenance: Incorporating accessible components and user-friendly designs, these valves facilitate quick and hassle-free maintenance, reducing downtime and maintenance costs.

- Safety Features: Some cooling tower valves are equipped with safety features such as fail-safe mechanisms or pressure relief valves to prevent system damage and ensure operator safety.

Advantages of Cooling Tower Valves

- Optimized Cooling Performance: Cooling tower valves enable precise control over fluid flow, ensuring optimal cooling tower operation and performance.

- Energy Efficiency: By regulating flow rates and minimizing wastage, these valves contribute to energy savings and reduced operating costs.

- Extended Equipment Lifespan: Efficient cooling tower valve operation helps prevent overheating and excessive wear on equipment, prolonging the lifespan of cooling system components.

- Customizable Solutions: Cooling tower valves are available in various sizes, materials, and configurations, allowing for tailored solutions to meet specific application requirements.

- Enhanced System Reliability: With durable construction and reliable performance, these valves minimize the risk of system failures or downtime, enhancing overall system reliability.

The Specifications of Cooling Tower Valves

| Specification | Details |

|---|---|

| Type | Ball Valve, Butterfly Valve, Gate Valve, etc. |

| Ball Material | Stainless Steel, Brass, PVC, etc. |

| Attachment Type | Flanged, Threaded, Welded, Victaulic, Grooved, etc. |

| Thread Standard | ANSI, BSPP, NPT, DIN, JIS, ISO, etc. |

| Thread Size | Varied depending on valve size and type |

| Body Material | Cast Iron, Carbon Steel, Stainless Steel, PVC, etc. |

| Safe for Use With | Water, Chemicals, Oil, Gas, Steam, etc. |

| Handle Type | Lever, Handwheel, Gear Operated, Actuator, etc. |

| Handle Material | Steel, Aluminum, Stainless Steel, PVC, etc. |

| Maximum Working Pressure | Varies depending on valve size, type, and material |

| Maximum Working Pressure | Varies depending on valve size, type, and material |

| Operating Pressure | Varies based on system requirements and valve type |

The Parameter of Cooling Tower Valves

- Type: Cooling Tower Valves come in various types such as ball valves, butterfly valves, gate valves, etc., each offering unique characteristics suited for different applications.

- Ball Material: The material used for the valve’s ball component, including options like stainless steel, brass, PVC, etc., ensuring compatibility with the fluid and environmental conditions.

- Attachment Type: Specifies how the valve is attached to the pipeline, such as flanged, threaded, welded, Victaulic, or grooved, influencing installation and compatibility.

- Thread Standard: Indicates the standard used for valve threading, including ANSI, BSPP, NPT, DIN, JIS, ISO, etc., ensuring proper fitting with other components.

- Thread Size: Varied depending on valve size and type, dictating the size of the threaded connection for installation.

- Body Material: The material composing the valve’s body, such as cast iron, carbon steel, stainless steel, PVC, etc., chosen for durability and resistance to corrosion.

- Safe for Use With: Specifies the types of fluids the valve is designed to handle safely, including water, chemicals, oil, gas, steam, etc., ensuring compatibility with the intended application.

- Handle Type: Indicates the type of handle used for valve operation, such as lever, handwheel, gear-operated, actuator, etc., influencing ease of use and control.

- Handle Material: The material of the valve’s handle, including options like steel, aluminum, stainless steel, PVC, etc., chosen for durability and ease of operation.

- Maximum Working Pressure: Specifies the maximum pressure the valve can safely withstand, in psi and bar, ensuring reliable performance under various operating conditions.

- Operating Pressure: Indicates the recommended operating pressure for the valve, ensuring optimal performance and longevity.

The Operation Theory of Cooling Tower Valves

The operation theory of Cooling Tower Valves involves regulating the flow of fluids within cooling tower systems to maintain optimal operating conditions. These valves utilize various mechanisms, such as ball, butterfly, or gate configurations, to control the opening and closing of the flow passage. For instance, in a ball valve, a spherical disc inside the valve body is rotated by the handle to either allow or block the flow of fluid. Similarly, a butterfly valve uses a disk-shaped closure element that rotates perpendicular to the flow direction to regulate fluid flow. The operation of Cooling Tower Valves ensures precise control over fluid flow rates, enabling efficient cooling tower performance.

Moreover, specialized valves like the transmission cooler bypass valve are designed to regulate the flow of transmission fluid in automotive cooling systems. These valves maintain optimal transmission temperature by bypassing the transmission cooler when necessary, thus preventing overcooling and ensuring efficient transmission operation.

In addition, cool tire valve caps may refer to valve caps designed to maintain proper tire pressure and prevent air leakage, ensuring optimal tire performance and safety. While not directly related to Cooling Tower Valves, they exemplify the diverse applications of valve technology in various industries.

The Parameters Table of Cooling Tower Valves

| Parameter | Description |

|---|---|

| Type | Ball Valve, Butterfly Valve, Gate Valve, etc. |

| Ball Material | Stainless Steel, Brass, PVC, etc. |

| Attachment Type | Flanged, Threaded, Welded, Victaulic, Grooved, etc. |

| Thread Standard | ANSI, BSPP, NPT, DIN, JIS, ISO, etc. |

| Thread Size | Varied depending on valve size and type |

| Body Material | Cast Iron, Carbon Steel, Stainless Steel, PVC, etc. |

| Safe for Use With | Water, Chemicals, Oil, Gas, Steam, etc. |

| Handle Type | Lever, Handwheel, Gear Operated, Actuator, etc. |

| Handle Material | Steel, Aluminum, Stainless Steel, PVC, etc. |

| Maximum Working Pressure | Varies depending on valve size, type, and material |

| Operating Pressure | Varies based on system requirements and valve type |