Knife Gate Valve Symbol

The Application of Knife Gate Valve

Introducing the Flowserve Knife Gate Valve, a premier choice from trusted knife gate valves suppliers. Designed for various applications, including severe services, this valve excels in handling challenging media. Equipped with a pneumatic actuator, it offers efficient and precise control over flow rates, enhancing operational efficiency. The Flowserve Knife Gate Valve is ideal for severe service applications where reliable shut-off is paramount. Its robust construction and innovative design ensure durability and longevity even in the most demanding environments. Experience superior performance and unmatched reliability with the Flowserve Knife Gate Valve, tailored to meet the diverse needs of modern industries.

gate valve symbol

flanged gate valve symbol

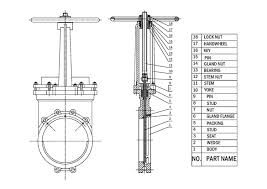

What Is Knife Gate Valve?

A Knife Gate Valve is a specialized type of valve designed to control the flow of fluid containing solids or slurry. It features a sharp-edged gate that slides across the flow path to either allow or block the flow. This design makes it particularly effective in applications where conventional valves may become clogged or obstructed. Knife Gate Valves are commonly used in industries such as mining, wastewater treatment, pulp and paper, and chemical processing, where reliable shut-off and handling of abrasive media are essential.

How Does Knife Gate Valve work?

A Knife Gate Valve operates by using a sharp-edged gate to control the flow of fluid. When the valve is open, the gate is lifted, allowing fluid to pass through. Closing the valve lowers the gate, blocking the flow. This design is effective for handling thick fluids, slurries, and solids, making it suitable for various industrial applications.

Features of Knife Gate Valve

- Versatile Application: Suitable for diverse industries including mining, wastewater treatment, and chemical processing.

- Robust Construction: Built with sturdy materials like stainless steel or cast iron for durability and reliability.

- Sharp-Edged Gate: Features a sharp-edged gate for precise flow control, even with thick fluids or solids.

- Bi-Directional Flow: Capable of controlling flow in both directions, enhancing flexibility in system design.

- Minimal Leakage: Provides tight sealing to prevent leakage, ensuring system integrity.

- Abrasion Resistance: Resistant to abrasion and wear, suitable for handling abrasive media.

- Easy Maintenance: Designed for easy maintenance, reducing downtime and operational costs.

- Various Actuation Options: Compatible with manual, pneumatic, or electric actuators for flexible operation.

- Compact Design: Space-saving design makes it suitable for installations with limited space.

Advantages of Knife Gate Valve

- Effective Flow Control: Provides precise control over the flow of fluids, including thick slurries and solids.

- Versatility: Suitable for a wide range of applications in industries such as mining, wastewater treatment, and chemical processing.

- Robust Construction: Built with durable materials like stainless steel or cast iron, ensuring longevity and reliability.

- Bi-Directional Sealing: Capable of sealing in both directions, enhancing system flexibility.

- Minimal Leakage: Offers tight sealing to prevent leakage, ensuring system integrity.

- Abrasion Resistance: Resistant to abrasion and wear, making it suitable for handling abrasive media.

- Easy Maintenance: Designed for easy maintenance, reducing downtime and operational costs.

- Various Actuation Options: Compatible with manual, pneumatic, or electric actuators for flexible operation.

- Cost-Effective: Provides cost-effective flow control solutions due to its efficiency, reliability, and low maintenance requirements.

The Specifications of Knife Gate Valve

| Specification | Details |

|---|---|

| Type | Knife Gate Valve |

| Gate Material | Stainless Steel, Cast Iron, Alloy Steel |

| Attachment Type | Lug, Wafer, Flanged |

| Thread Standard | ANSI B16.5, MSS-SP-81, EN 1092-1 |

| Thread Size | 2″, 3″, 4″, 6″, 8″, 10″, 12″, 14″, 16″, 18″, 20″, 24″ |

| Body Material | Cast Iron, Carbon Steel, Stainless Steel |

| Safe for Use With | Water, Sewage, Slurry, Pulp, Chemicals, Abrasive Media |

| Handle Type | Manual Handwheel, Gear Operator, Pneumatic or Hydraulic Actuator |

| Handle Material | Stainless Steel, Cast Iron, Aluminum |

| Maximum Working Pressure | Up to 150 psi (10 bar) |

| Operating Pressure | Varies depending on specific model and size, refer to manufacturer’s specifications |

The Parameter of Knife Gate Valve

- Type: Knife Gate Valve

- Gate Material: Stainless Steel, Cast Iron, Alloy Steel

- Attachment Type: Lug, Wafer, Flanged

- Thread Standard: ANSI B16.5, MSS-SP-81, EN 1092-1

- Thread Size: 2″, 3″, 4″, 6″, 8″, 10″, 12″, 14″, 16″, 18″, 20″, 24″

- Body Material: Cast Iron, Carbon Steel, Stainless Steel

- Safe for Use With: Water, Sewage, Slurry, Pulp, Chemicals, Abrasive Media

- Handle Type: Manual Handwheel, Gear Operator, Pneumatic or Hydraulic Actuator

- Handle Material: Stainless Steel, Cast Iron, Aluminum

- Maximum Working Pressure: Up to 150 psi (10 bar)

- Operating Pressure: Varies depending on specific model and size, refer to manufacturer’s specifications

The Operation Theory of Knife Gate Valve

- Gate Movement: When open, the gate of the Knife Gate Valve is lifted, allowing fluid to flow through the valve.

- Flow Control: Closing the valve lowers the gate, blocking the flow of fluid.

- Sealing Mechanism: The gate is designed to provide a tight seal against the valve seat when closed, preventing leakage.

- Suitable Applications: These valves are commonly used in industries such as mining, wastewater treatment, and pulp and paper, where reliable shut-off and handling of abrasive media are crucial.

- Variety of Designs: Manufacturers like Clarkson, DSS, and Fabri offer a range of Knife Gate Valve designs tailored to specific application requirements, ensuring optimal performance and efficiency.

The Parameters Table of Knife Gate Valve

| Parameter | Details |

|---|---|

| Type | Knife Gate Valve |

| Gate Material | Stainless Steel, Cast Iron, Alloy Steel |

| Attachment Type | Lug, Wafer, Flanged |

| Thread Standard | ANSI B16.5, MSS-SP-81, EN 1092-1 |

| Thread Size | 2″, 3″, 4″, 6″, 8″, 10″, 12″, 14″, 16″, 18″, 20″, 24″ |

| Body Material | Cast Iron, Carbon Steel, Stainless Steel |

| Seat Material | EPDM, Natural Rubber, Nitrile, Metal (Stainless Steel) |

| Stem Material | Stainless Steel, Carbon Steel |

| Bonnet Material | Cast Iron, Carbon Steel, Stainless Steel |

| Packing Material | PTFE, Graphite |

| Maximum Working Pressure (psi) | Up to 150 psi (depending on size and material) |

| Maximum Working Pressure (bar) | Up to 10 bar (depending on size and material) |

| Operating Temperature | Up to 180°C (356°F) |