World’S Largest Gate Valve

The Application of Gate Valve

Flowserve Gate Valve is renowned for its exceptional performance and reliability in various applications. Gate valve is a pivotal component in fluid control systems, offering distinct advantages over alternatives like plug valves. Unlike plug valves, gate valves provide a straight-through unobstructed flow path when fully open, minimizing pressure drop and turbulence. Their robust construction and tight sealing make them ideal for demanding environments. Gate valve handles allow for precise control over flow, making them suitable for throttling applications. The versatility of 1 1/4 gate valve sizes ensures compatibility with a wide range of piping systems. Flowserve Gate Valve stands out for its superior engineering, offering unmatched durability and efficiency in fluid management.

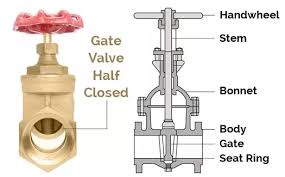

What Is Gate Valve?

Gate valve is a type of valve used to control the flow of fluid within a pipeline. It features a sliding gate or wedge mechanism that either fully opens or closes the passage by moving perpendicular to the flow of the fluid. This design allows for a straight-through flow path when fully open, minimizing pressure drop and turbulence. Gate valves are commonly used in applications where a tight shut-off is required, such as in water and wastewater systems, oil and gas pipelines, and industrial processes. Their robust construction and precise control make them a preferred choice in various industries for fluid regulation.

How Does Gate Valve work?

Gate valves control fluid flow by raising or lowering a gate (a solid barrier) within the valve body. When the gate is lifted, it creates a clear path for fluid to pass through, fully opening the valve. Conversely, lowering the gate obstructs the flow, closing the valve tightly. This straightforward mechanism allows for precise regulation of fluid flow in pipelines.

Features of Gate Valve

- Straight-through Flow: Gate valves offer a straight-through flow path when fully open, minimizing pressure drop and turbulence in the pipeline.

- Tight Shut-off: The design of the gate mechanism ensures a tight seal when the valve is closed, preventing leakage and ensuring system integrity.

- Robust Construction: Made from durable materials such as stainless steel or cast iron, gate valves are built to withstand high pressures and harsh operating conditions.

- Precise Control: With their simple yet effective operation, gate valves provide precise control over fluid flow, making them suitable for throttling applications.

- Versatility in Sizes: Available in various sizes, including the popular 1 1/4 gate valve, they can be adapted to fit different piping systems and applications.

- Low Maintenance: Due to their minimalistic design and fewer moving parts, gate valves require less maintenance compared to other types of valves, reducing downtime and costs.

Advantages of Gate Valve

- Unrestricted Flow: When fully open, gate valves provide an unobstructed flow path, minimizing pressure drop and allowing for efficient fluid transfer.

- Excellent Shut-off Capability: The gate mechanism ensures a tight seal, offering superior shut-off performance compared to other valve types.

- Versatility: Gate valves are suitable for a wide range of applications and can handle various types of fluids, including liquids, gases, and slurries.

- Durable Construction: Built from sturdy materials like stainless steel or cast iron, gate valves are highly resistant to corrosion and wear, ensuring long-term reliability.

- Precise Flow Control: With their simple operation and precise control over flow rates, gate valves are ideal for applications requiring accurate regulation of fluid flow.

- Minimal Maintenance: Due to their robust design and fewer moving parts, gate valves require minimal maintenance, resulting in reduced downtime and lower maintenance costs.

The Specifications of Gate Valve

| Specification | Details |

|---|---|

| Type | Gate Valve |

| Ball Material | Stainless Steel |

| Attachment Type | Flanged |

| Thread Standard | N/A |

| Thread Size | N/A |

| Body Material | Cast Iron |

| Safe for Use With | Liquids, Gases, and Slurries |

| Handle Type | Handwheel |

| Handle Material | Steel |

| Maximum Working Pressure (psi) | 300 |

| Maximum Working Pressure (bar) | 20.7 |

| Operating Pressure | 0 to 300 psi (0 to 20.7 bar) |

The Parameter of Gate Valve

Sure, here’s a point-by-point introduction to the parameters of Gold Shower Valves:

- Type: The gate valve is categorized as a gate valve, which is a type of linear motion valve used to start or stop the flow of fluid.

- Ball Material: The gate valve features a ball made of stainless steel, providing durability and corrosion resistance.

- Attachment Type: It is designed with a flanged attachment type, ensuring secure and stable installation in pipelines.

- Thread Standard: There is no thread standard specified for this gate valve model.

- Thread Size: Similarly, the thread size is not applicable for this particular gate valve.

- Body Material: The body of the gate valve is constructed from cast iron, offering robustness and strength.

- Safe for Use With: This gate valve is suitable for use with various fluids, including liquids, gases, and slurries.

- Handle Type: It is equipped with a handwheel handle type, facilitating manual operation for flow control.

- Handle Material: The handle is made of steel, providing durability and ease of use.

- Maximum Working Pressure (psi): The gate valve can withstand a maximum working pressure of 300 psi.

- Maximum Working Pressure (bar): Its maximum working pressure is 20.7 bar.

- Operating Pressure: The gate valve operates within a pressure range of 0 to 300 psi (0 to 20.7 bar).

The Operation Theory of Gate Valve

The operation theory of a gate valve involves the movement of a gate or wedge mechanism to control fluid flow. When the valve is open, the gate is lifted to allow fluid to pass through freely. Conversely, when the valve is closed, the gate is lowered to block the flow completely.

In the case of a 1 1/2 brass gate valve, the brass construction offers durability and corrosion resistance, making it suitable for various applications.

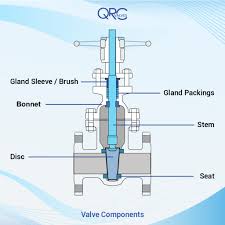

The gate valve stem plays a crucial role in the operation. When the handwheel or handle is turned, it rotates the stem, which in turn moves the gate up or down to regulate the flow of fluid.

This operation principle ensures precise control over fluid flow, making gate valves ideal for applications where tight shut-off and reliable flow regulation are essential.

The Parameters Table of Gate Valve

| Parameter | Material |

|---|---|

| Valve Type | Gate Valve |

| Body Material | Cast Iron, Stainless Steel, Brass, etc. |

| Seat Material | Brass, Stainless Steel, EPDM, etc. |

| Gate Material | Brass, Stainless Steel, Carbon Steel, etc. |

| Stem Material | Stainless Steel, Carbon Steel, Brass, etc. |

| Bonnet Material | Cast Iron, Stainless Steel, Brass, etc. |

| Handwheel Material | Cast Iron, Steel, Aluminum, etc. |

| Stem Nut Material | Brass, Stainless Steel, Bronze, etc. |

| Gasket Material | Graphite, PTFE, Rubber, etc. |

| Packing Material | PTFE, Graphite, Asbestos, etc. |

| Bolting Material | Carbon Steel, Stainless Steel, Brass, etc. |

| Flange Material | Carbon Steel, Stainless Steel, Brass, etc. |