SEATING SYSTEMS FOR ABRASIVE & DIRTY SERVICE

forged steel globe valve

globe control valves

globe valve cv

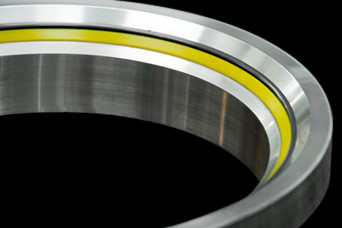

Composite Seating

Since leather was married with timber to improve the bow, composite solutions have reduced the need to compromise. Yet most manufacturers only offer a single seat insert solution. Service considerations include temperature, media type, pressure etc. In the end materials like Nylon, Devlon and PEEK® are a compromise that must serve many masters. Hard seat inserts have no resilience or memory for indentations and can have trouble sealing at very low pressures and yet these materials increase the valves torque and reduce the temperature range.

APV offers double and triple seating solutions utilising metal, teflon, hard Viton, Devlon etc. In addition we can supply special ‘cam action’ axial lift seats that lift off during opening and closing protecting the seat from high velocity and abrasive damage.

Seat types include:-

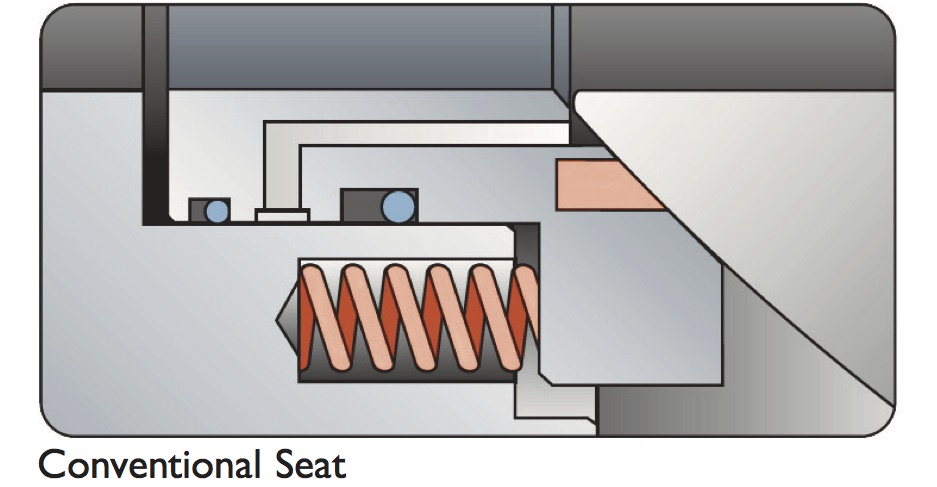

A-PMSS®-Primary Metal Secondary Seal

This design provides ‘metal to metal’ class IV or V shut off in addition to API598 zero leakage provided by a resilient seat insert. This is a conventional seating design but APV optionally reduces the standard metal to metal tolerances for drip tight or bubble tight applications.

A-PMSS+S®-Primary Metal Secondary Seal + Scraper

The A-PMSS+S® design is the same as the A-PMSS® above except for the addition of a scraper. On conventional trunnion ball valve seating systems, APV offers the A-PR-PMSS+S® seat design option. A protective scraper ring is inserted in front of the soft seat insert to remove solid particles, dirt or debris that could damage or clog the contact area between ball and soft seat insert ring. This feature assures that the working area of the seat will be clean allowing the seats to work effectively. This design prolongs seat life whilst only minimally increasing cost and is particularly advantageous for valves that cannot be removed from the line for repair such as butt-weld valves, welded body valves, buried service valves as well as known non clean service applications.

A-DRS®-Double Resilient Seal

This design marries teflon or an elastomeric seal such as hard viton which has excellent memory providing indentation resilience with Devlon, Nylon or PEEK® which handle higher pressures but are also more scratch resistant. Even with this system there is still primary metal to metal seating but it is not mate lapped like in the A-PMSS® Seat.

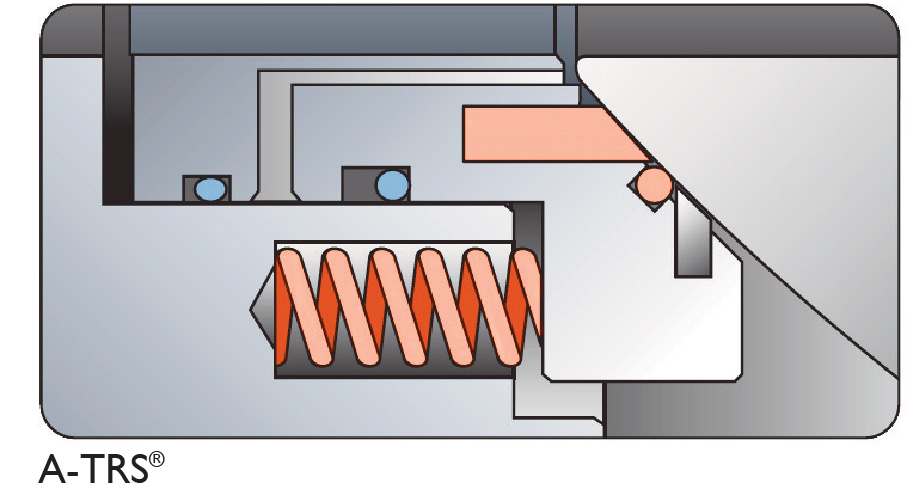

TRS®-Triple Resilient Seal

In addition to Double Resilient Seal® a third hardened Viton resilient seal is added which has more resilience to indentation and ensures a bubble tight seal even at very low pressures. This third seal will still also handle high pressures even if the other two seals fail. Many manufacturers use this as their only seal.

The above systems are ideal for applications that require redundant sealing and where access to repair the valve is not feasible. Lower torque and lower shut off pressures are additional advantages of this design.

In summary, these seating systems provide a much longer leak free life at a lower cost compared to metal to metal seated ball valves and can supplied in quicker delivery. These seating systems offer the additional advantages of lower torque as well as high and very low pressure sealing assurance.

APV can also hard coat and treat ball and/or seat with low friction sinterised coatings to reduce friction coefficient and solve wedging problems.

Trunnion Mounted Ball Valves

APV Conventional Soft Seat Insert

APV seat inserts can be ordered in a variety of materials whilst still complying to API seat test requirements for “bubble-tight shut off” for oil & gas applications as well as specialised fluid transmission applications in chemical and mining sectors.

APV Conventional Soft Seat Insert + Scraper

The A-PMSS+S® design is the same as the A-PMSS® above except for the addition of a scraper. On conventional trunnion ball valve seating systems, APV offers the A-PR-PMSS+S® seat design option (8” and above). A protective scraper ring is inserted in front of the soft seat insert to remove solid particles, dirt or debris that could damage or clog the contact area between ball and soft seat insert ring. This feature assures that the working area of the seat will be clean allowing the seats to work effectively. This design prolongs seat life whilst only minimally increasing cost and is particularly advantageous for valves that cannot be removed from the line for repair such as buttweld valves, welded body valves, buried service valves as well as known non clean service applications.

APV Composite Seal Seat System

APV Double or Triple seal seat design is ideal for applications that require redundant sealing when start up conditions are known to have debris in the line and where removing the valve is not possible. This design offers lower torque and superior low pressure shut-off whilst providing zero leakage reliability at an affordable price compared to metal seated. Multiple material types are employed for each seal providing a combination of resilient and super hard properties to deal with a wide range of entrained particulates and debris. Even if one or even two of the seals are damaged an effective seal can usually be maintained.

APV Metal to Metal Seats

APV has extensive experience in the supply of valves for applications such as high temperature corrosive and/or erosive/abrasive environments. Various hard face material can be employed on the ball and seat face. Refer to the Metal to Metal seated section.