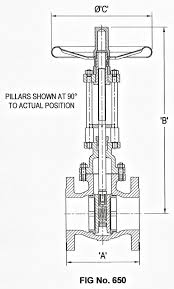

Parallel Slide Gate Valves

The Application of parallel slide gate valves

Cameron, a renowned gate valves manufacturer, offers premium solutions like parallel slide gate valves ideal for various applications in Australia. These valves, distinct from conventional knife gate valves, ensure precise control of fluid flow through parallel movement of gates. Engineered with reliability in mind, they’re suitable for high-pressure environments, providing efficient shut-off capabilities.

Actuated gate valves by Cameron further enhance operational flexibility, allowing remote control and automation. Their design minimizes friction, ensuring smooth operation and longevity. As one of the leading slide gate valves manufacturers globally, Cameron prioritizes durability and performance, meeting stringent industry standards. In Australia, where demanding conditions prevail, these valves stand out for their reliability and robustness, making them indispensable in diverse industrial settings.

What Is parallel slide gate valves?

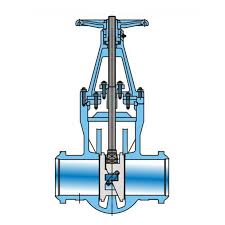

Parallel slide gate valves are a type of valve used to control the flow of fluids in pipelines. Unlike traditional gate valves, they feature parallel gates that move in opposite directions to regulate flow. This design minimizes friction, ensuring smooth operation and tight shut-off. Parallel slide gate valves are often preferred in applications requiring precise flow control and high-pressure environments due to their reliable performance and durability. They are commonly used in industries such as oil and gas, chemical processing, and water treatment.

How Does parallel slide gate valves work?

Parallel slide gate valves operate by utilizing parallel gates that move perpendicular to the direction of flow. When the valve is open, the gates retract into the valve body, allowing fluid to pass through freely. To close the valve, the gates are pushed against the flow, creating a tight seal that prevents fluid from passing. This design minimizes friction, ensuring smooth operation and efficient flow control.

Features of parallel slide gate valves

- Parallel Gates: Utilize parallel gates for precise flow control, each moving independently to regulate fluid passage.

- Minimal Friction: Design minimizes friction between gates and valve body, ensuring smooth operation and extended lifespan.

- Tight Shut-Off: Achieve secure sealing with gates pressed firmly against the flow direction, preventing leakage when the valve is closed.

- High Pressure Capability: Suitable for high-pressure environments, providing reliable performance even under extreme conditions.

- Durability: Constructed with robust materials to withstand harsh operating conditions, enhancing longevity and minimizing maintenance needs.

- Versatility: Adaptable for various applications across industries such as oil and gas, chemical processing, and water treatment.

- Actuation Compatibility: Compatible with actuation systems for remote operation and automation, enhancing operational efficiency.

- Compliance: Manufactured to meet industry standards and regulations, ensuring safety and reliability in operation.

- Easy Maintenance: Simplified design facilitates maintenance tasks, reducing downtime and operational disruptions.

Advantages of parallel slide gate valves

- Precise Flow Control: Enable accurate regulation of fluid flow due to the parallel movement of gates, ensuring optimal performance.

- Minimal Friction Loss: Reduce energy consumption and operational costs by minimizing friction between the gates and valve body during operation.

- Tight Sealing: Provide reliable sealing to prevent leakage, maintaining system integrity and safety.

- High Pressure Handling: Capable of withstanding high-pressure environments, making them suitable for demanding applications.

- Long Service Life: Designed with durable materials and minimal wear points, resulting in extended service life and reduced maintenance requirements.

- Versatility: Adapt to various fluids and operating conditions, making them suitable for a wide range of industries and applications.

- Automation Compatibility: Easily integrate with automation systems for remote operation and control, enhancing efficiency and safety.

- Reduced Maintenance: Require minimal maintenance due to their robust design and fewer moving parts, reducing downtime and operational costs.

- Compliance: Manufactured to meet industry standards and regulations, ensuring safety and reliability in operation.

The Specifications of parallel slide gate valves

Sure, here are the specifications for the parallel slide gate valves in tabular form:

| Specification | Details |

|---|---|

| Type | Parallel Slide Gate Valve |

| Ball Material | Stainless Steel, Carbon Steel, or Cast Iron |

| Attachment Type | Flanged or Threaded |

| Thread Standard | ASME B1.20.1 or equivalent |

| Thread Size | 1/2 inch to 24 inches |

| Body Material | Ductile Iron, Cast Steel, Stainless Steel |

| Safe for Use With | Water, Oil, Gas, Chemicals, Steam |

| Handle Type | Handwheel, Gear Operator, Actuator |

| Handle Material | Stainless Steel, Carbon Steel, Aluminum |

| Maximum Working Pressure (psi) | Up to 1500 psi |

| Maximum Working Pressure (bar) | Up to 103.4 bar |

| Operating Pressure | 10 psi to 1500 psi (0.7 bar to 103.4 bar) |

The Parameter of parallel slide gate valves

- Type: Parallel Slide Gate Valve

- Ball Material Options: Stainless Steel, Carbon Steel, Cast Iron

- Attachment Types Available: Flanged or Threaded

- Thread Standard: ASME B1.20.1 or equivalent

- Thread Size Range: From 1/2 inch to 24 inches

- Body Material Choices: Ductile Iron, Cast Steel, Stainless Steel

- Safe for Use With: Water, Oil, Gas, Chemicals, Steam

- Handle Types: Handwheel, Gear Operator, Actuator

- Handle Material Options: Stainless Steel, Carbon Steel, Aluminum

- Maximum Working Pressure (psi): Up to 1500 psi

- Maximum Working Pressure (bar): Up to 103.4 bar

- Operating Pressure Range: From 10 psi to 1500 psi (0.7 bar to 103.4 bar)

The Operation Theory of parallel slide gate valves

The operation theory of parallel slide gate valves is rooted in their unique design, akin to that of a rising stem gate valve. When the valve is opened, the stem and gates rise together, allowing fluid to pass through the parallel gates unobstructed. Conversely, when the valve is closed, the stem and gates descend, pressing against the flow to create a tight seal. This design minimizes the risk of a stuck gate valve, as the parallel gates move independently and are less prone to jamming.

In terms of maintenance, gate valve stem replacement is simplified due to the rising stem design. By lifting the stem, operators can easily access and replace worn components, ensuring continued functionality and longevity of the valve. Overall, the operation theory of parallel slide gate valves emphasizes reliability, ease of use, and efficient flow control in various industrial applications.

The Parameters Table of parallel slide gate valves

| Parameter | Details |

|---|---|

| Type | Parallel Slide Gate Valve |

| Ball Material Options | Stainless Steel, Carbon Steel, Cast Iron |

| Gate Material | Stainless Steel, Carbon Steel, Cast Iron |

| Stem Material | Stainless Steel, Carbon Steel |

| Seat Material | Metal, PTFE (Teflon), EPDM, NBR (Nitrile) |

| Bonnet Material | Ductile Iron, Cast Steel, Stainless Steel |

| Body Material | Ductile Iron, Cast Steel, Stainless Steel, Carbon Steel |

| Disc Material | Stainless Steel, Carbon Steel, Cast Iron |

| Packing Material | Graphite, PTFE (Teflon), EPDM, NBR (Nitrile) |

| Gasket Material | Graphite, PTFE (Teflon), EPDM, NBR (Nitrile) |

| Bolt/Nut Material | Stainless Steel, Carbon Steel, Alloy Steel |

| Flange Material | Carbon Steel, Stainless Steel |

| Operating Mechanism | Handwheel, Gear Operator, Actuator |