Actuated Valve – Working Principle and Types

The Application of Actuated Valve

Introducing actuated valves, essential components for automated fluid control systems. Cameron offers a diverse range of actuated valves tailored to various industries. One such example is the Pentair 263045 180 degree 3-port pool and spa valve actuator, designed for pool and spa applications. This pool valve actuator facilitates seamless control over water flow direction, ensuring optimal functionality and convenience. Utilizing a pneumatic actuator valve, it offers reliable operation and precise control, enhancing efficiency and performance. Whether in pool and spa systems or industrial processes, actuated valves play a crucial role in streamlining operations and maximizing productivity.

What Are The Types Of Actuated Valve?

- Ball Valves: Actuated ball valves feature a spherical disc with a hole for fluid flow, controlled by an actuator to open or close the valve.

- Butterfly Valves: Actuated butterfly valves use a rotating disc to regulate flow, offering quick operation and low-pressure drop.

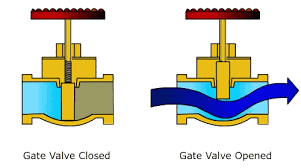

- Gate Valves: Actuated gate valves employ a gate mechanism to control flow, suitable for on/off applications and high-pressure environments.

- Globe Valves: Actuated globe valves utilize a disc moving perpendicular to the flow direction, providing precise flow control and throttling capabilities.

- Diaphragm Valves: Actuated diaphragm valves use a flexible diaphragm to regulate flow, ideal for controlling corrosive or abrasive fluids.

- Check Valves: Actuated check valves allow flow in one direction while preventing backflow, ensuring system integrity and safety.

- Plug Valves: Actuated plug valves use a cylindrical or tapered plug to control flow, suitable for applications requiring tight shut-off.

- Pinch Valves: Actuated pinch valves employ a flexible tube pinched by a mechanism to regulate flow, suitable for handling slurries or viscous fluids.

What Is Actuated Valve?

Actuated valves are essential components in automated fluid control systems. They feature an actuator mechanism that enables remote operation, allowing for precise control over fluid flow. Actuated valves come in various types, including ball valves, butterfly valves, gate valves, and more, each suited to different applications. By integrating an actuator, these valves streamline processes, improve efficiency, and enhance safety by eliminating the need for manual operation. They find extensive use in industries such as oil and gas, water treatment, pharmaceuticals, and manufacturing, where reliable and automated fluid control is critical.

How Does Actuated Valve?

Actuated valves operate by integrating an actuator with a traditional valve mechanism. The actuator, powered by pneumatic, electric, or hydraulic systems, controls the opening and closing of the valve to regulate fluid flow. When activated, the actuator applies force to the valve mechanism, either opening or closing it as needed based on system parameters. This automation allows for precise and remote control over fluid flow, enhancing efficiency and accuracy in various industrial processes.

Features of Actuated Valve

- Automation: Actuated valves feature automation capabilities, allowing for remote operation and control without the need for manual intervention, enhancing operational efficiency.

- Precision: With precise control over fluid flow, actuated valves ensure accurate regulation of flow rates and system parameters, minimizing wastage and optimizing performance.

- Versatility: These valves come in various types and sizes, catering to a wide range of applications and industries, from water treatment to oil and gas.

- Reliability: Designed for robustness and durability, actuated valves offer reliable performance even in demanding environments, ensuring continuous operation with minimal downtime.

- Safety: By automating fluid control processes, actuated valves enhance safety by reducing the risk of human error and minimizing exposure to hazardous environments.

- Flexibility: They can be integrated with different types of actuators, including pneumatic, electric, and hydraulic, providing flexibility in system design and operation.

Advantages and Disadvantages of Actuated Valve

Advantages:

- Automation: Actuated valves enable automation, reducing the need for manual operation and enhancing process efficiency.

- Precision: They offer precise control over fluid flow, allowing for accurate regulation of flow rates and system parameters.

- Versatility: Actuated valves come in various types and sizes, suitable for a wide range of applications and industries.

- Reliability: Designed for robustness and durability, actuated valves provide reliable performance even in demanding environments.

- Safety: By automating fluid control processes, actuated valves enhance safety by minimizing human error and reducing exposure to hazardous environments.

Disadvantages:

- Complexity: Actuated valves can be more complex than manual valves, requiring additional components such as actuators and controllers.

- Cost: The initial cost of actuated valves and their associated components may be higher compared to manual valves.

- Maintenance: Actuated valves may require more frequent maintenance due to the additional components involved, increasing operational costs.

- Power Dependency: Actuated valves rely on power sources such as electricity or compressed air for operation, making them vulnerable to power outages.

The Specifications of Actuated Valve

| Specification | Value |

|---|---|

| Type | Actuated Valve |

| Ball Material | Stainless Steel, Brass, Bronze, PVC, etc. |

| Attachment Type | Threaded, Flanged, Welded, etc. |

| Thread Standard | ANSI B1.20.1, BSPT, NPT, etc. |

| Thread Size | 1/2 inch, 3/4 inch, 1 inch, etc. |

| Body Material | Stainless Steel, Brass, Bronze, Cast Iron, PVC, etc. |

| Safe for Use With | Water, Oil, Gas, Steam, Chemicals, etc. |

| Handle Type | Manual, Electric, Pneumatic, Hydraulic, etc. |

| Handle Material | Stainless Steel, Aluminum, Plastic, etc. |

| Maximum Working Pressure (psi) | 150 psi, 300 psi, 600 psi, etc. |

| Maximum Working Pressure (bar) | 10.3 bar, 20.7 bar, 41.4 bar, etc. |

| Operating Pressure | 0-100 psi, 0-200 psi, 0-400 psi, etc. |

The Installation Steps for Actuated Valve

- Preparation: Gather all necessary tools and equipment, including wrenches, bolts, nuts, and any specialized tools required for the specific valve and actuator.

- Shut Off System: Ensure the system where the actuated valve will be installed is completely shut off and depressurized to prevent accidents.

- Mounting: Attach the actuator to the valve according to the manufacturer’s instructions, ensuring proper alignment and secure fastening.

- Connection: Connect the actuated valve to the existing piping system using appropriate fittings and adapters, ensuring a tight and leak-free connection.

- Wiring or Piping: If the actuator is electrically operated, wire it according to the manufacturer’s instructions. For pneumatic actuators, connect the air supply line.

- Calibration: Calibrate the actuated valve according to the system requirements, adjusting settings such as opening and closing speeds, torque limits, and position feedback if applicable.

- Testing: Conduct a functional test to ensure the actuated valve operates correctly. This may involve cycling the valve through its full range of motion, checking for smooth operation and proper sealing.

- Final Checks: Verify that all connections are tight and secure, and there are no visible signs of leaks or damage before putting the system back into service.

The Operation Theory of Actuated Valve

Air Actuated Valve: Air actuated valves utilize compressed air to control the valve’s operation. When the actuator receives a signal, it directs the compressed air to move a piston or diaphragm, which in turn operates the valve to open or close.Actuated Ball Valve: Actuated ball valves feature a spherical disc with a hole for fluid flow. The pneumatic or electric actuator rotates the ball within the valve body to regulate flow, providing quick and reliable on/off control.Pneumatic Valve Actuator: Pneumatic valve actuators convert air pressure into mechanical motion to operate valves. The actuator’s piston or diaphragm moves in response to changes in air pressure, which translates into the valve’s opening or closing action.

The Parameters Chart of Actuated Valve

| Parameter | Material Options |

|---|---|

| Valve Type | Ball Valve, Butterfly Valve, Gate Valve, etc. |

| Valve Body | Stainless Steel, Brass, Bronze, Cast Iron, PVC, etc. |

| Valve Trim | Stainless Steel, Brass, Bronze, PTFE, Rubber, etc. |

| Actuator Type | Pneumatic, Electric, Hydraulic, Manual, etc. |

| Actuator Housing | Aluminum Alloy, Stainless Steel, Plastic, etc. |

| Stem | Stainless Steel, Carbon Steel, Brass, Bronze, etc. |

| Seals | Nitrile, EPDM, Viton, PTFE, etc. |

| Mounting | Flanged, Threaded, Wafer, Lug, etc. |

| Accessories | Solenoid Valve, Positioner, Limit Switch, etc. |