Electric 3-Way Mixing Type Control Valve

The Application of Electric 3-Way Mixing Type Control Valve

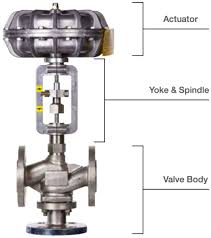

Introducing the Electric 3-Way Mixing Type Control Valve by Cameron, a leading brand in industrial solutions. This versatile 3-way control valve efficiently regulates fluid flow in heating, ventilation, and air conditioning (HVAC) systems. Incorporating innovative technology, the 3-way thermostatic control valve ensures precise temperature control by mixing hot and cold fluids as per system requirements. Ideal for diverse applications, it optimizes energy usage and maintains optimal comfort levels. Trust Cameron for superior quality and performance in fluid control solutions.

What Are The Types Of Electric 3-Way Mixing Type Control Valve?

- Two-Port Electric 3-Way Mixing Valve: This type of valve has two inlet ports and one outlet port. It regulates the flow of two different fluids or streams into a common outlet, allowing for blending or mixing of the fluids in desired proportions. It’s commonly used in HVAC systems for temperature control by mixing hot and cold water.

- Three-Port Electric 3-Way Mixing Valve: This valve features three ports: one inlet port and two outlet ports. It controls the diversion of fluid flow between the two outlets, allowing for the selection of either one of the outlets or a mixture of both. It’s utilized in applications where fluid diversion or distribution is required, such as in heating systems with multiple zones.

What Is Electric 3-Way Mixing Type Control Valve?

The Electric 3-Way Mixing Type Control Valve is a device used to regulate the flow and temperature of fluids in heating, ventilation, and air conditioning (HVAC) systems. It features three ports: one inlet and two outlets. By adjusting the position of its internal components, it controls the blending of hot and cold fluids to achieve the desired temperature output, ensuring efficient and precise temperature control in various applications.

How to Select the Right Electric 3-Way Mixing Type Control Valve?

Selecting the right Electric 3-Way Mixing Type Control Valve involves considering factors such as flow rate, temperature range, fluid compatibility, and system pressure. Determine the required valve size, material construction, and actuator type based on the specific application needs and operating conditions. Conduct thorough research and consult with industry experts to ensure optimal valve selection for your system requirements.

Features of Electric 3-Way Mixing Type Control Valve

- Versatility: Electric 3-Way Mixing Type Control Valves are highly versatile, accommodating various fluid mixing applications in HVAC systems, radiant floor heating, and industrial processes.

- Precise Temperature Control: These valves offer precise temperature regulation by blending hot and cold fluids in desired proportions, ensuring consistent and comfortable environmental conditions.

- Energy Efficiency: By dynamically adjusting fluid flow and temperature, these valves optimize energy usage, leading to reduced operating costs and environmental impact.

- Compact Design: Featuring a compact and space-saving design, they are ideal for installations with limited space constraints, offering flexibility in system layout.

- Easy Integration: Designed for seamless integration into automation systems, these valves support remote control and monitoring, enhancing system efficiency and convenience.

- Durable Construction: Constructed from high-quality materials, Electric 3-Way Mixing Type Control Valves exhibit excellent durability, reliability, and longevity even in demanding operating conditions.

- Low Maintenance: With minimal moving parts and robust construction, these valves require minimal maintenance, resulting in lower downtime and maintenance costs over their lifespan.

- Wide Range of Sizes and Configurations: Available in various sizes and configurations, they can be tailored to suit specific flow rates, pressure ratings, and installation requirements, ensuring compatibility with diverse applications.

Advantages and Disadvantages of Electric 3-Way Mixing Type Control Valve

Advantages:

- Precise Temperature Control: Enables accurate blending of hot and cold fluids, ensuring consistent temperature output.

- Energy Efficiency: Optimizes energy usage by dynamically adjusting fluid flow, reducing operating costs.

- Versatility: Suitable for various applications in HVAC, industrial processes, and radiant floor heating.

- Compact Design: Space-saving design facilitates installation in tight spaces.

- Easy Integration: Supports seamless integration into automation systems for remote control and monitoring.

Disadvantages:

- Complexity: Requires careful selection and setup to ensure proper operation.

- Initial Cost: Higher initial investment compared to simpler valve types.

- Maintenance: May require periodic maintenance due to the complexity of internal components.

- Potential Leakage: Complex design increases the risk of leakage if not installed or maintained properly.

- Limited Flow Capacity: May have limitations in handling high flow rates compared to other valve types.

The Specifications of Electric 3-Way Mixing Type Control Valve

| Specification | Details |

|---|---|

| Type | Electric 3-Way Mixing Control Valve |

| Ball Material | Stainless Steel |

| Attachment Type | Flanged |

| Thread Standard | N/A |

| Thread Size | N/A |

| Body Material | Brass |

| Safe for Use With | Water, HVAC fluids, chemicals |

| Handle Type | Electric actuator |

| Handle Material | N/A |

| Maximum Working Pressure (psi) | 150 |

| Maximum Working Pressure (bar) | 10.3 |

| Operating Pressure | 5-100 psi |

The Installation Steps for Electric 3-Way Mixing Type Control Valve

- Preparation:

- Gather all necessary tools and equipment, including wrenches, pipe tape, and a pipe cutter.

- Ensure the work area is clean and free from debris.

- Shut Off Utilities:

- Turn off the main power supply to the system to prevent accidental activation during installation.

- Close the valves on both the hot and cold water supply lines.

- Positioning:

- Identify the optimal location for the valve installation based on system requirements and accessibility.

- Ensure sufficient space around the valve for maintenance and future adjustments.

- Pipe Preparation:

- Cut the pipes to the required length using a pipe cutter.

- Remove any burrs or debris from the pipe ends using a deburring tool.

- Attachment:

- Attach the valve to the existing piping system using appropriate fittings and connectors.

- Ensure proper alignment and secure attachment to prevent leaks.

- Sealing:

- Apply pipe tape or thread sealant to the threaded connections to ensure a tight seal.

- Tighten the connections using wrenches to the manufacturer’s recommended torque specifications.

- Electrical Connection:

- Connect the electric actuator of the valve to the control system using the provided wiring.

- Follow the manufacturer’s instructions for wiring connections and polarity.

- Testing:

- Open the main water supply valves.

- Gradually increase the power supply to the valve and test its operation.

- Check for leaks and ensure proper functioning of the valve in mixing hot and cold fluids to achieve the desired temperature.

- Adjustment:

- Fine-tune the valve settings as necessary to achieve the desired temperature output.

- Adjust the actuator position or control system settings according to system requirements.

- Final Inspection:

- Inspect the installation for any signs of leaks, loose connections, or other issues.

- Ensure all components are securely fastened and properly aligned.

- Confirm that the valve is operating correctly and meeting the desired performance criteria.

The Operation Theory of Electric 3-Way Mixing Type Control Valve

- Fluid Diversion: Electric 3-Way Mixing Type Control Valves have three ports: one inlet and two outlets. Depending on the valve’s position, fluid flow can be directed to either one of the outlets or a mixture of both. This enables the valve to divert the flow of fluid as needed to achieve the desired system conditions.

- Temperature Control: In temperature control applications, these valves regulate the temperature of the fluid by blending hot and cold fluids in varying proportions. By adjusting the position of the internal components, the valve controls the ratio of hot and cold fluid entering the mixing chamber, thereby regulating the temperature of the mixed fluid at the outlet.

- Actuation: Electric 3-Way Mixing Type Control Valves are actuated by electric actuators, which receive signals from a control system or operator. The actuator moves the internal components of the valve to the desired position based on the input signal, allowing for precise control over fluid flow and temperature.

- Feedback Control (Optional): Some advanced systems may incorporate feedback mechanisms such as temperature sensors or flow meters to provide real-time information about the system conditions. This feedback allows the control system to adjust the valve position accordingly to maintain the desired temperature or flow rate.