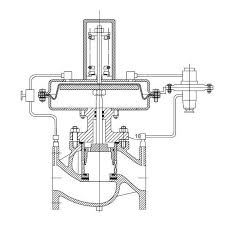

Model TT-EZ100 Single-Seat Control Valves

The Application of Seat Control Valves

Cameron is a trusted brand known for its innovative industrial solutions, including seat control valves. Specifically, in applications like air ride seat control valve and air seat control valve, Cameron’s valves play a vital role. These valves regulate the flow of air to adjust the seat position, ensuring optimal comfort and support for vehicle occupants. Additionally, in systems like exhaust valve control, Cameron’s seat control valves manage exhaust flow to optimize engine performance. With robust construction and reliable performance, Cameron’s seat control valves are essential for various automotive and industrial applications.

What Are The Types Of Seat Control Valves?

- Globe Valves: These valves feature a linear motion disk or plug and are suitable for applications requiring fine throttling control.

- Butterfly Valves: Butterfly valves have a disk-shaped closure element that rotates on an axis perpendicular to the flow direction. They offer quick operation and are ideal for large flow applications.

- Ball Valves: Ball valves use a spherical closure element with a hole in the middle to control flow. They provide excellent shut-off capability and are commonly used in high-pressure applications.

- Diaphragm Valves: Diaphragm valves use a flexible diaphragm to regulate flow. They are suitable for handling corrosive or abrasive fluids and offer tight shut-off capability.

- Plug Valves: Plug valves use a cylindrical or tapered plug to control flow. They are versatile and can handle a wide range of flow rates and pressures.

- Pinch Valves: Pinch valves use a flexible tube or sleeve to control flow by pinching the tube closed. They are ideal for handling slurries and abrasive fluids.

- Needle Valves: Needle valves have a long, tapered needle-like stem that provides precise flow control in low-flow applications

What Is Seat Control Valves?

Seat control valves are specialized components used in fluid control systems to regulate the flow of fluids by controlling the position of a movable element against a fixed seat. These valves ensure precise control over flow rates, allowing for throttling, isolation, or diversion of fluids in various industrial, commercial, and residential applications. With their ability to provide tight shut-off and accurate flow control, seat control valves play a crucial role in maintaining process efficiency and safety. They come in different types and configurations to suit specific application requirements, offering versatility and reliability in fluid control systems.

How to Select the Right Seat Control Valves?

Selecting the right seat control valves involves considering factors such as the application requirements, fluid characteristics, pressure and temperature conditions, and desired flow rates. Evaluate the valve’s compatibility with the system, its control mechanism, and the required level of precision. Consulting with valve experts can provide valuable insights for optimal selection.

Features of Seat Control Valves

- Precise Control:

- Accurate: Provides precise control over flow rates, allowing for fine adjustments to meet specific process requirements.

- Throttling Capability: Offers the ability to throttle the flow of fluids, ensuring optimal process performance.

- Reliable Shut-Off:

- Tight Seal: Ensures tight shut-off to prevent leakage and maintain system integrity.

- Durable Construction: Features robust materials and construction for reliable operation and longevity.

- Versatility:

- Multiple Applications: Suitable for a wide range of applications, including industrial processes, HVAC systems, and water treatment.

- Various Configurations: Available in different types and configurations to suit specific application requirements.

- Compatibility:

- Fluid Compatibility: Compatible with a wide range of fluids, including liquids, gases, and slurries.

- Pressure and Temperature Ratings: Designed to handle varying pressure and temperature conditions, ensuring reliable performance in diverse environments.

- Ease of Maintenance:

- Accessible Design: Features an accessible design for easy maintenance and repair, minimizing downtime and operational disruptions.

- Replaceable Components: Allows for easy replacement of worn or damaged parts, extending the valve’s service life.

- Control Mechanism:

- Manual or Automated Control: Offers options for manual operation or automated control, providing flexibility based on application needs.

- Actuation Options: Can be actuated by handwheel, lever, pneumatic, electric, or hydraulic actuators, depending on the application requirements.

Advantages and Disadvantages of Seat Control Valves

Advantages:

- Precise Flow Control:

- Allows for precise regulation of flow rates, ensuring accurate process control and optimization.

- Reliable Shut-Off:

- Provides tight shut-off to prevent leakage and maintain system integrity, enhancing safety and efficiency.

- Versatility:

- Suitable for a wide range of applications and fluid types, offering flexibility in system design and operation.

- Durable Construction:

- Constructed from robust materials, ensuring long-term reliability and minimal maintenance requirements.

Disadvantages:

- Initial Cost:

- Seat control valves may have a higher initial cost compared to simpler valve types, potentially increasing the upfront investment in system installation.

- Complexity:

- Some seat control valves can be more complex to install and maintain, requiring specialized knowledge and expertise.

- Pressure Drop:

- Certain types of seat control valves may introduce a pressure drop across the valve, affecting system efficiency in high-pressure applications.

The Specifications of Seat Control Valves

| Specification | Details |

|---|---|

| Type | Seat Control Valve |

| Ball Material | Stainless Steel, Brass, PVC, etc. |

| Attachment Type | Threaded, Flanged, Welded, etc. |

| Thread Standard | NPT, BSP, BSPT, DIN, etc. |

| Thread Size | 1/2″, 3/4″, 1″, or customized |

| Body Material | Carbon Steel, Stainless Steel, Brass, PVC, etc. |

| Safe for Use With | Water, Air, Oil, Chemicals, etc. |

| Handle Type | Lever, Knob, Actuator, etc. |

| Handle Material | Aluminum, Stainless Steel, Plastic, etc. |

| Maximum Working Pressure (psi) | Up to 5000 psi (varies by model) |

| Maximum Working Pressure (bar) | Up to 345 bar (varies by model) |

| Operating Pressure | Dependent on system requirements |

The Installation Steps for Seat Control Valves

- Preparation:

- Gather all necessary tools and equipment, including wrenches, thread sealant, and pipe fittings.

- Ensure the work area is clean and free from debris.

- Valve Inspection:

- Examine the valve for any visible damage or defects.

- Verify that the valve specifications match the requirements of the system.

- Select Location:

- Choose an appropriate location for installing the valve, considering accessibility and operational requirements.

- Ensure sufficient space for maintenance and operation.

- Shut Off System:

- Shut off the flow of fluid to the system where the valve will be installed.

- Release any pressure in the system to prevent accidents during installation.

- Prepare Pipes:

- Clean the pipe ends thoroughly to remove any dirt or debris.

- Apply thread sealant or tape to the male threads of the pipes.

- Mount Valve:

- Position the valve in the desired orientation on the pipeline.

- Use appropriate fittings to secure the valve to the pipeline, ensuring a tight seal.

- Connect Pipes:

- Screw the pipe ends into the valve ports, ensuring proper alignment and tightening to prevent leaks.

- Use a wrench to tighten the connections securely, but avoid over-tightening.

- Test for Leaks:

- Once the valve is installed, pressurize the system and check for any leaks around the valve connections.

- If leaks are detected, tighten the connections further or apply additional sealant as needed.

- Final Checks:

- Confirm that the valve operates smoothly and functions correctly in regulating fluid flow.

- Label the valve for easy identification and maintenance in the future.

- System Activation:

- Restore the flow of fluid to the system and verify that the valve operates as expected under normal operating conditions.

The Operation Theory of Seat Control Valves

- Seat Control Valves:

- Seat control valves regulate fluid flow by controlling the position of a movable element against a fixed seat.

- These valves ensure precise control over flow rates, allowing for throttling, isolation, or diversion of fluids in various applications.

- By providing tight shut-off and accurate flow control, seat control valves maintain process efficiency and safety.

- Water Control Valves:

- Water control valves manage the flow and pressure of water in plumbing systems, irrigation, and industrial processes.

- These valves control the flow rate, direction, and distribution of water, ensuring optimal performance and efficiency in water-related applications.

- Air Volume Control Valves:

- Air volume control valves regulate the volume and pressure of air in HVAC systems, pneumatic equipment, and air compressors.

- These valves adjust the airflow to maintain desired pressure levels, temperature control, and air distribution in heating, ventilation, and air conditioning systems.

The Parameters Chart of Seat Control Valves

| Parameter | Details |

|---|---|

| Valve Type | Seat Control Valve |

| Body Material | Stainless Steel, Brass, Carbon Steel, PVC, etc. |

| Seat Material | PTFE, EPDM, Viton, Stainless Steel, etc. |

| Stem Material | Stainless Steel, Brass, Carbon Steel, etc. |

| Ball Material | Stainless Steel, Brass, PVC, etc. |

| Seal Material | Nitrile, Viton, EPDM, Silicone, etc. |

| Actuator Type | Manual, Pneumatic, Electric, Hydraulic, etc. |

| Actuator Material | Aluminum, Stainless Steel, Plastic, etc. |

| Connection Type | Threaded, Flanged, Welded, etc. |

| Thread Standard | NPT, BSP, BSPT, DIN, etc. |

| Thread Size | 1/2″, 3/4″, 1″, or customized |

| Maximum Pressure | Up to XXX psi/bar (varies by model) |

| Temperature Range | -XX°C to XX°C (varies by model) |