Pneumatic Boiler Blowdown Control Valves

The Application of Pneumatic Boiler Blowdown Control Valves

Cameron is a trusted provider of industrial solutions, offering advanced hydraulic control valves for various applications. Specifically, in pneumatic boiler blowdown systems, Cameron’s hydraulic flow control valves play a critical role. These valves regulate the release of water and steam from the boiler to maintain optimal pressure and prevent damage. By precisely managing the flow of gas and liquid, Cameron’s valves ensure safe and efficient boiler operation. With robust construction and reliable performance, Cameron’s pneumatic boiler blowdown control valves are essential for maintaining boiler integrity and safety.

What Are The Types Of Pneumatic Boiler Blowdown Control Valves?

- Quick Opening Valves: These valves provide rapid release of boiler water and steam during blowdown cycles, ensuring efficient removal of impurities and maintaining optimal boiler performance.

- Slow Opening Valves: Slow opening valves offer gradual release of boiler blowdown, minimizing the risk of water hammer and thermal shock to the boiler system components.

- Modulating Valves: Modulating valves allow for precise control over the blowdown flow rate, adjusting according to the boiler’s operating conditions and requirements. This helps optimize boiler efficiency and reduce energy consumption.

- Pressure-Relief Valves: Pressure-relief valves are designed to automatically open and release excess pressure buildup in the boiler, safeguarding against overpressure situations and potential damage to the system.

- Continuous Blowdown Valves: These valves provide a continuous discharge of boiler water to control the concentration of dissolved solids, preventing scale buildup and corrosion within the boiler.

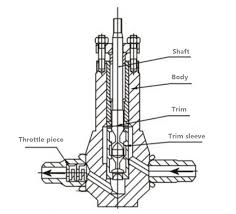

What Is Pneumatic Boiler Blowdown Control Valves?

Pneumatic boiler blowdown control valves are specialized components used in steam boiler systems to regulate the discharge of water and steam during blowdown processes. These valves, typically operated pneumatically, help maintain optimal boiler conditions by removing impurities and preventing the buildup of sediment and scale. By controlling the flow of water and steam, pneumatic boiler blowdown control valves ensure safe and efficient boiler operation while minimizing the risk of damage and improving overall system performance.

How to Select the Right Pneumatic Boiler Blowdown Control Valves?

Selecting the right pneumatic boiler blowdown control valves involves considering factors such as boiler pressure, blowdown rate, valve size, and material compatibility. Assess the specific requirements of the boiler system and consult with experts to ensure the chosen valves can effectively manage blowdown processes while maintaining system integrity and efficiency.

Features of Pneumatic Boiler Blowdown Control Valves

- Pressure Regulation:

- Maintains: Ensures boiler pressure within safe limits by regulating blowdown flow.

- Prevents: Prevents overpressure situations that can lead to boiler damage.

- Efficient Blowdown:

- Rapid Release: Allows for quick discharge of water and steam during blowdown cycles.

- Optimizes: Optimizes blowdown process for efficient removal of impurities.

- Precision Control:

- Accurate: Provides precise control over blowdown flow rate and duration.

- Adjustable: Allows adjustment according to boiler operating conditions and requirements.

- Reliability:

- Robust Design: Features durable construction for reliable performance in demanding boiler environments.

- Minimizes Downtime: Reduces downtime and maintenance needs, ensuring continuous boiler operation.

- Safety:

- Prevents Damage: Helps prevent damage to boiler components by controlling blowdown effectively.

- Safeguards: Safeguards against overpressure situations and potential boiler accidents.

- Compatibility:

- Material Options: Available in various materials to suit different boiler system requirements and fluid compatibilities.

- Flexible Installation: Suitable for a range of boiler sizes and configurations.

Advantages and Disadvantages of Pneumatic Boiler Blowdown Control Valves

Advantages:

- Efficient Blowdown:

- Ensures rapid discharge of water and steam, optimizing boiler performance.

- Pressure Regulation:

- Maintains boiler pressure within safe limits, preventing damage and ensuring operational safety.

- Precision Control:

- Provides accurate adjustment of blowdown flow rate, enhancing system efficiency.

- Reliability:

- Features robust construction for reliable performance in demanding boiler environments.

- Safety:

- Safeguards against overpressure situations, minimizing the risk of boiler accidents.

Disadvantages:

- Complexity:

- May require specialized knowledge for proper selection, installation, and maintenance.

- Cost:

- Initial investment and maintenance costs may be higher compared to simpler blowdown control methods.

- Maintenance:

- Requires regular inspection and maintenance to ensure proper functioning, potentially leading to increased downtime.

The Specifications of Pneumatic Boiler Blowdown Control Valves

| Specification | Details |

|---|---|

| Type | Pneumatic Boiler Blowdown Control Valve |

| Ball Material | Stainless Steel, Brass, or PVC |

| Attachment Type | Threaded or Flanged |

| Thread Standard | NPT (National Pipe Thread) or BSP |

| Thread Size | 1/2″, 3/4″, 1″, or customized |

| Body Material | Carbon Steel, Stainless Steel, Brass, PVC |

| Safe for Use With | Water, Steam, Air, Chemicals |

| Handle Type | Lever, Knob, or Actuator |

| Handle Material | Aluminum, Stainless Steel, Plastic |

| Maximum Working Pressure (psi) | Up to 500 psi (varies by model) |

| Maximum Working Pressure (bar) | Up to 34 bar (varies by model) |

| Operating Pressure | Dependent on system requirements |

The Installation Steps for Pneumatic Boiler Blowdown Control Valves

- Preparation:

- Gather all necessary tools and equipment, including wrenches, thread sealant, and pipe fittings.

- Ensure the work area is clean and free from debris.

- Valve Inspection:

- Examine the valve for any visible damage or defects.

- Verify that the valve specifications match the requirements of the boiler system.

- Select Location:

- Choose an appropriate location for installing the valve, considering accessibility and operational requirements.

- Ensure sufficient space for maintenance and operation.

- Shut Off System:

- Shut off the flow of water and steam to the boiler system where the valve will be installed.

- Release any pressure in the system to prevent accidents during installation.

- Prepare Pipes:

- Clean the pipe ends thoroughly to remove any dirt or debris.

- Apply thread sealant or tape to the male threads of the pipes.

- Mount Valve:

- Position the valve in the desired orientation on the pipeline.

- Use appropriate fittings to secure the valve to the pipeline, ensuring a tight seal.

- Connect Pipes:

- Screw the pipe ends into the valve ports, ensuring proper alignment and tightening to prevent leaks.

- Use a wrench to tighten the connections securely, but avoid over-tightening.

- Test for Leaks:

- Once the valve is installed, pressurize the boiler system and check for any leaks around the valve connections.

- If leaks are detected, tighten the connections further or apply additional sealant as needed.

- Final Checks:

- Confirm that the valve operates smoothly and functions correctly in regulating blowdown flow.

- Label the valve for easy identification and maintenance in the future.

- System Activation:

- Restore the flow of water and steam to the boiler system and verify that the valve operates as expected under normal operating conditions.

The Operation Theory of Pneumatic Boiler Blowdown Control Valves

- Pneumatic Boiler Blowdown Control Valves:

- These valves regulate the discharge of water and steam during blowdown cycles in steam boiler systems.

- Pneumatic actuators control the valve position, allowing for precise adjustment of blowdown flow rate and duration.

- By managing blowdown effectively, these valves help maintain optimal boiler conditions and prevent damage.

- Modulating Control Valves:

- Modulating control valves regulate fluid flow by continuously adjusting the valve position in response to control signals.

- They offer precise control over flow rates, allowing for dynamic adjustment to meet changing system conditions.

- Commonly used in HVAC systems, process control, and industrial automation applications for precise fluid regulation.

- Shower Temperature Control Valves:

- These valves regulate the flow of hot and cold water to maintain a consistent temperature in shower systems.

- Temperature-sensitive elements within the valve mechanism adjust the flow of hot and cold water to achieve the desired temperature set by the user.

- Shower temperature control valves ensure user comfort and safety by preventing sudden temperature fluctuations.

The Parameters Chart of Pneumatic Boiler Blowdown Control Valves

| Parameter | Details |

|---|---|

| Valve Type | Pneumatic Boiler Blowdown Control Valve |

| Body Material | Stainless Steel, Brass, Carbon Steel, PVC |

| Ball Material | Stainless Steel, Brass, or PVC |

| Stem Material | Stainless Steel, Brass, or Carbon Steel |

| Seat Material | PTFE, EPDM, Viton, or Stainless Steel |

| Seal Material | Nitrile, Viton, EPDM, or Stainless Steel |

| Actuator Type | Pneumatic |

| Actuator Material | Aluminum, Stainless Steel, or Plastic |

| Connection Type | Threaded or Flanged |

| Thread Standard | NPT, BSP, BSPT, or DIN |

| Thread Size | 1/2″, 3/4″, 1″, or customized |

| Maximum Working Pressure (psi) | Up to 500 psi (varies by model) |

| Maximum Working Pressure (bar) | Up to 34 bar (varies by model) |

| Operating Pressure | Dependent on system requirements |