What is a Spring Loaded Check Valve?

1 2 globe valve

2 globe valve

1 globe valve

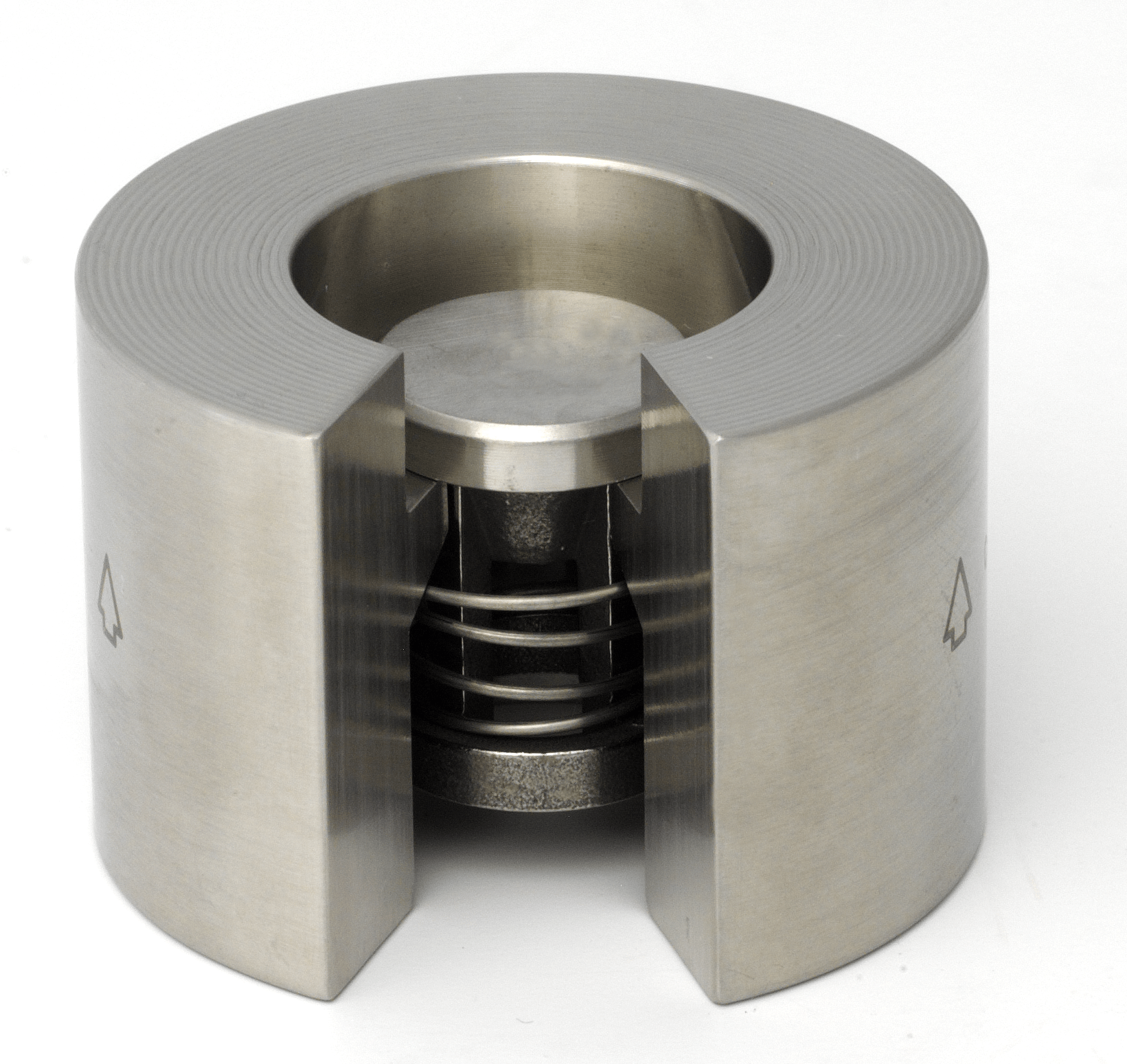

A spring loaded check valve (a.k.a. spring check valve) incorporates a spring to assist in closing the check valve. They are designed to close prior to fluid flow reversal. Preventing backflow eliminates the hydraulic shock also known as water hammer. Water hammer is a result of the sudden fluid stoppage of flow in a fluid process system. All valves Check-All manufactures are inline check valves. We offer multiple seat materials and spring cracking pressures to meet all of your application needs.

Please refer to the list below to find your desired style.

- Wafer

- Sanitary

- Weld

- Threaded

- Tubing

- Insert

- Housed

- Mini

- Custom

Style F1, F6, FP

The Flange Insert Check Valve can be installed in any ANSI class 150, 300, or 600 flanged connection in the system, horizontally or vertically with no alterations to existing pipe necessary. Simply spread a flanged joint, insert the valve, and tighten the bolts. View More

Style WV

The Wafer Insert Check Valve has a “drop-in” body style that fits inside the bolt circle between two mating ANSI flanges. Quick and easy installations and removal in rigid piping applications. Many valves in this series meet API 594 requirements. View More

Style LP

The Lined Pipe Insert Check Valve is designed to fit between two flanges on most lined pipe systems. No gaskets are required, just spread the flanges, center the valve, and bolt the flang. View More