Ceramic Valve

The Application of Ceramic Valve

The application of ceramic valve technology has revolutionized the industry with its durability and efficiency. Brands like Cameron have integrated ceramic disk valve designs to enhance performance in harsh environments. The ceramic disc valve benefits include resistance to corrosion, wear, and high temperatures, making them ideal for various industrial applications.

What Are The Types Of Ceramic Valve?

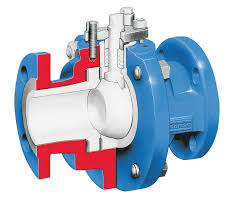

- Ball Valves: These use a spherical ceramic ball that rotates to open and close the valve. They provide tight shutoff and are resistant to corrosion.

- Plug Valves: Ceramic plug valves use a tapered ceramic plug that slides in and out of the valve body to control flow. They are durable and provide good flow control.

- Butterfly Valves: Ceramic butterfly valves use a rotary disc to regulate flow. They are compact, lightweight, and offer good flow characteristics.

- Diaphragm Valves: These use a ceramic diaphragm that flexes to open and close the valve. They are well-suited for slurries and abrasive fluids.

- Gate Valves: Ceramic gate valves have a sliding gate that moves across the flow path to open and close the valve. They provide tight shutoff and are often used for on/off service.

- Globe Valves: Ceramic globe valves use a movable ceramic disc that seats against a fixed ring to control flow. They offer good throttling capabilities.

What Is Ceramic Valve?

A ceramic valve is a type of industrial valve that utilizes ceramic materials instead of traditional metal components. Ceramic is an extremely durable and corrosion-resistant material, making ceramic valves well-suited for handling harsh, abrasive, or high-temperature fluids and gases in industries such as petrochemical, chemical processing, and power generation. These valves offer advantages like extended service life, reduced maintenance, and superior performance compared to their metal counterparts. The ceramic components, such as the ball, plug, or diaphragm, provide the valve with enhanced resistance to wear, chemical attack, and thermal cycling, allowing for reliable operation in demanding applications.

How to Select the Right Ceramic Valve?

Fluid Compatibility: Determine the chemical composition and operating conditions of the fluid to ensure the ceramic materials are compatible and can withstand any corrosive or abrasive properties. Process Parameters: Assess the required flow rates, pressure, and temperature ranges to choose a valve size and design suitable for the process. Installation Requirements: Consider the valve’s size, mounting orientation, and end connection type to ensure it fits the available space and piping configuration. Performance Needs: Evaluate the valve’s shutoff, throttling, and cycle life capabilities to match the specific application requirements. Cost and Availability: Compare the procurement, installation, and lifetime ownership costs of different ceramic valve options to find the best value.

Careful consideration of these factors will help engineers select the ceramic valve that provides the optimal balance of performance, reliability, and cost-effectiveness for the intended service.

Features of Ceramic Valve

Corrosion Resistance: Ceramic materials are highly resistant to chemical corrosion, making them well-suited for aggressive fluid environments.

Thermal Stability: Ceramic valves can withstand high temperatures, often up to 1000°C, allowing them to be used in hot process applications.

Abrasion Resistance: The hardness of ceramic components provides excellent resistance to wear and abrasion, extending the valve’s service life.

Low Maintenance: Ceramic valves require minimal lubrication and have longer intervals between overhauls compared to metal valves.

Non-Stick Properties: The smooth, non-porous ceramic surfaces inhibit buildup of deposits, reducing the risk of valve fouling.

High Purity: Ceramic materials do not contaminate the process fluid, making them suitable for hygienic and ultra-pure applications.

Compact Design: Ceramic valves can be manufactured in smaller sizes due to the inherent strength of the ceramic materials.

Advantages and Disadvantages of Ceramic Valve

Advantages of Ceramic Valves:

Corrosion Resistance: Ceramic materials are highly resistant to chemical corrosion, making them well-suited for aggressive fluid environments.

Thermal Stability: Ceramic valves can withstand high temperatures, often up to 1000°C, allowing them to be used in hot process applications.

Abrasion Resistance: The hardness of ceramic components provides excellent resistance to wear and abrasion, extending the valve’s service life.

Low Maintenance: Ceramic valves require minimal lubrication and have longer intervals between overhauls compared to metal valves.

Non-Stick Properties: The smooth, non-porous ceramic surfaces inhibit buildup of deposits, reducing the risk of valve fouling.

High Purity: Ceramic materials do not contaminate the process fluid, making them suitable for hygienic and ultra-pure applications.

Compact Design: Ceramic valves can be manufactured in smaller sizes due to the inherent strength of the ceramic materials.

Disadvantages of Ceramic Valves:

Brittleness: Ceramic materials are inherently brittle and can be susceptible to cracking or chipping under high mechanical stresses.

Higher Cost: Ceramic valves generally have a higher initial purchase cost compared to their metal counterparts.

Limited Size Range: Ceramic valves are typically available in smaller sizes, limiting their use in high-flow applications.

Specialized Installation: Proper handling and installation practices are required to avoid damaging the ceramic components.

Limited Availability: The selection of ceramic valve models and suppliers may be more limited than for traditional metal valves.

The Specifications of Ceramic Valve

| Specification | Value |

|---|---|

| Type | 2-Piece Ball Valve |

| Ball Material | 95% Alumina Ceramic |

| Attachment Type | Threaded Ends |

| Thread Standard | NPT |

| Thread Size | 1/2 inch |

| Body Material | 316 Stainless Steel |

| Safe for Use With | Acids, Bases, Solvents, Cryogenic Fluids |

| Handle Type | Lever Handle |

| Handle Material | Stainless Steel |

| Maximum Working Pressure (psi) | 500 psi |

| Maximum Working Pressure (bar) | 34.5 bar |

| Operating Pressure | 0-500 psi (0-34.5 bar) |

The Installation Steps for Ceramic Valve

- Inspect the Valve: Carefully inspect the ceramic valve and its components to ensure there are no visible defects or damages prior to installation.

- Clean the Pipe Connections: Thoroughly clean the pipe threads and sealing surfaces to remove any dirt, rust, or debris that could interfere with the valve’s proper installation and sealing.

- Apply Thread Sealant: Apply a suitable thread sealant, such as PTFE tape or pipe dope, to the valve’s threaded connections to ensure a tight, leak-free seal.

- Position the Valve: Align the valve in the desired orientation and direction of flow, ensuring that the inlet and outlet ports are correctly positioned.

- Tighten the Connections: Carefully thread the valve into the pipe connections and tighten the joints using a wrench. Avoid over-tightening, which can potentially crack the ceramic components.

- Inspect for Leaks: Once the valve is installed, slowly pressurize the system and check for any leaks around the valve body, stem, or connections. Tighten the connections further if necessary.

- Operate the Valve: Actuate the valve several times to ensure smooth and complete opening and closing. Adjust the packing gland or stem if any binding or excessive force is required.

- Insulate the Valve: If the valve is to be used in high-temperature applications, ensure that appropriate insulation is installed to protect the surrounding components and personnel.

- Document the Installation: Record the valve’s location, installation date, and any other relevant information for future reference and maintenance purposes.

The Operation Theory of Ceramic Valve

Operation Theory of Ceramic Valves:

- Sealing Mechanism: Ceramic valves typically utilize a ball or plug design that rotates within a ceramic seat to provide a tight, leak-proof seal. The smooth, non-porous ceramic surfaces create a near-zero coefficient of friction, ensuring reliable and long-lasting sealing performance.

- Thermal Expansion: The thermal expansion coefficients of ceramic materials are generally lower than those of metals. This property helps maintain the valve’s sealing integrity and dimensional stability even in high-temperature environments.

- Chemical Resistance: The inherent chemical inertness of ceramic materials makes them highly resistant to corrosion, erosion, and chemical attack from a wide range of aggressive fluids and environments.

Industrial Ceramic Valve Applications:

- Chemical Processing: Ceramic valves are widely used in the chemical industry for handling corrosive, abrasive, or high-purity substances, such as acids, bases, solvents, and specialty chemicals.

- Petrochemical Industry: Ceramic valves are employed in refineries, petrochemical plants, and pipelines to control the flow of fuels, lubricants, and other hydrocarbon-based fluids.

- Semiconductor Manufacturing: The high purity and cleanliness of ceramic valves make them essential components in semiconductor fabrication and other microelectronics processes.

- Pharmaceutical and Biotechnology: Ceramic valves are used in the production, storage, and distribution of pharmaceutical and biotechnology products, where strict sanitary requirements and material compatibility are critical.

- Power Generation: Ceramic valves are utilized in power plants, both conventional and nuclear, to handle high-temperature steam, feedwater, and other process fluids.

- Cryogenic Applications: The thermal stability of ceramic materials allows their use in cryogenic applications, such as the handling of liquefied gases like oxygen, nitrogen, and natural gas.

- Specialty Applications: Ceramic valves may also find use in other industries, such as food and beverage processing, aerospace, and research laboratories, where their unique properties provide significant advantages.