Blowdown Valve – Working Principle, Types, Diagram, Applications

The Application of Blowdown Valve

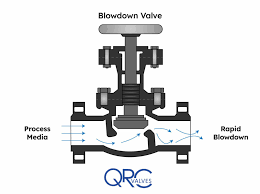

Introducing Cameron’s innovative solutions in the realm of blowdown valves for the oil and gas industry. The blowdown valve function is critical in ensuring safety and efficiency in industrial operations. Specifically designed to rapidly depressurize equipment or pipelines, blowdown valves serve a crucial purpose in preventing overpressurization, equipment damage, and potential hazards to personnel.

In the realm of oil and gas, where safety and reliability are paramount, Cameron’s blowdown valves stand out for their robust construction, precision engineering, and adherence to industry standards. These valves are engineered to withstand harsh operating conditions and provide swift and effective blowdown when required, safeguarding assets and personnel alike.

What Are The Types Of Blowdown Valve?

- Angle Type Blowdown Valve: These valves feature an angled body design, allowing for efficient blowdown of liquids or gases from piping systems.

- ** Globe Type Blowdown Valve**: Globe valves are commonly used for blowdown applications due to their precise flow control capabilities and ability to handle high pressures.

- Ball Type Blowdown Valve: Ball valves offer quick and reliable shut-off, making them suitable for blowdown operations where rapid depressurization is required.

- Gate Type Blowdown Valve: Gate valves are used in blowdown systems where a straight-line flow path and minimal pressure drop are essential.

- Diaphragm Type Blowdown Valve: Diaphragm valves provide tight shut-off and are suitable for blowdown applications involving corrosive or abrasive fluids.

- Pilot-Operated Blowdown Valve: These valves utilize a pilot valve to control the opening and closing of the main valve, allowing for precise and remote operation.

- Thermal Relief Valve: Thermal relief valves are designed to relieve excess pressure caused by temperature fluctuations in equipment or piping systems, preventing damage and ensuring safety.

What Is Blowdown Valve?

Blowdown valves are essential components in industrial systems designed to quickly release or “blow down” pressurized fluids or gases from equipment or pipelines. This rapid depressurization helps prevent overpressure situations, safeguarding equipment, personnel, and the environment. Blowdown valves are crucial for maintaining safety and operational efficiency in various industries, including oil and gas, chemical processing, power generation, and refining. They come in different types and configurations to suit specific applications, offering reliable and effective pressure relief solutions.

How to Select the Right Blowdown Valve?

Selecting the right blowdown valve involves considering factors such as system pressure, fluid type, flow rate, and operating conditions. Begin by assessing the required pressure relief capacity and the maximum allowable blowdown pressure. Consider the material compatibility with the fluid being handled and any corrosive or abrasive properties. Additionally, evaluate the valve’s design features, such as valve type, size, and actuation method, to ensure it meets the specific requirements of the application. Prioritize reliability, safety, and ease of maintenance when making your selection to ensure optimal performance and longevity.

Features of Blowdown Valve

- Rapid Depressurization:

- Blowdown valves are designed to facilitate swift depressurization of equipment or pipelines to prevent overpressure situations.

- Pressure Relief:

- These valves provide effective pressure relief by quickly releasing excess pressure from the system.

- Safety Mechanism:

- Acting as a safety mechanism, blowdown valves help protect equipment, personnel, and the environment from potential hazards associated with overpressure.

- Material Compatibility:

- They are available in various materials to ensure compatibility with different fluids and operating conditions, enhancing reliability and longevity.

- Versatility:

- Blowdown valves come in different types and configurations, including angle type, globe type, and ball type, offering versatility to suit various applications.

- Precise Control:

- These valves offer precise control over the blowdown process, allowing operators to adjust the release of pressure as needed.

- Ease of Maintenance:

- Many blowdown valves are designed for easy maintenance, with features such as accessible internals and replaceable parts, minimizing downtime and maintenance costs.

- Compliance:

- They meet industry standards and regulations for pressure relief, ensuring compliance with safety requirements and guidelines.

Advantages and Disadvantages of Blowdown Valve

Advantages:

- Pressure Relief: Blowdown valves provide effective relief from excess pressure in equipment or pipelines, preventing potential hazards.

- Safety Enhancement: They enhance safety by preventing overpressure situations that could lead to equipment failure or accidents.

- Prevent Damage: Blowdown valves help prevent damage to equipment and piping systems by releasing pressure before it reaches critical levels.

- Versatility: These valves come in various types and configurations, offering versatility to suit different applications and operating conditions.

Disadvantages:

- Limited Functionality: Blowdown valves primarily serve the purpose of pressure relief and may not offer additional control features.

- Potential for Fluid Loss: Rapid depressurization through blowdown valves can result in the loss of fluids or gases from the system.

- Maintenance Requirements: Like any mechanical device, blowdown valves require regular maintenance to ensure proper functioning, adding to operational costs.

- System Complexity: Incorporating blowdown valves into a system adds complexity to the overall design and operation, requiring careful integration and management.

The Specifications of Blowdown Valve

| Specification | Details |

|---|---|

| Type | Angle Type Blowdown Valve |

| Ball Material | Stainless Steel |

| Attachment Type | Flanged |

| Thread Standard | ANSI B16.5 |

| Thread Size | 2 inches |

| Body Material | Carbon Steel |

| Safe for Use With | Oil, Gas, Water |

| Handle Type | Manual |

| Handle Material | Carbon Steel |

| Maximum Working Pressure (psi) | 1500 psi |

| Maximum Working Pressure (bar) | 103.42 bar |

| Operating Pressure | 0-500 psi |

The Installation Steps for Blowdown Valve

- Preparation:

- Gather all necessary tools and equipment required for installation.

- Ensure the work area is clear and safe for installation activities.

- Valve Positioning:

- Identify the ideal location for the blowdown valve in the piping system, considering accessibility and safety.

- Valve Mounting:

- Securely mount the blowdown valve to the pipeline using appropriate bolts and gaskets.

- Ensure proper alignment of the valve to facilitate smooth operation.

- Attachment Connection:

- Connect the blowdown valve to the piping system using flanged or threaded connections, depending on the valve design and system requirements.

- Tighten the connections to the recommended torque specifications to prevent leaks.

- Actuator Installation:

- If the blowdown valve includes an actuator, install it according to the manufacturer’s instructions.

- Connect any necessary wiring or tubing for actuation and control.

- Pressure Relief Setup:

- Set the desired pressure relief parameters on the blowdown valve, considering the system’s operating pressure and safety requirements.

- Testing:

- Conduct a thorough functional test of the blowdown valve to ensure proper installation and operation.

- Verify the valve’s response to pressure relief commands and its ability to relieve excess pressure effectively.

- Calibration:

- Calibrate the blowdown valve as needed to ensure accurate pressure relief and optimal performance.

- Adjust settings such as blowdown pressure and flow rate to meet system requirements.

- Documentation:

- Maintain detailed records of the installation steps, test results, and calibration settings for future reference.

- Update system documentation and diagrams to reflect the new blowdown valve installation.

- Training:

- Provide training to relevant personnel on the operation, maintenance, and troubleshooting of the blowdown valve system.

The Operation Theory of Blowdown Valve

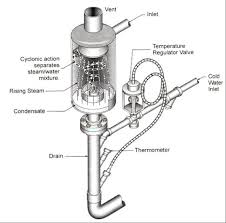

- Continuous Blowdown Valve:

- Continuous blowdown valves are designed to maintain optimal water quality in boiler systems by continuously removing a small amount of water to control the concentration of dissolved solids.

- These valves operate automatically or semi-automatically based on preset parameters, such as time or conductivity levels, ensuring consistent water quality and preventing scale buildup.

- Safety Valve Blowdown:

- Safety valve blowdown refers to the periodic or emergency release of pressure from safety valves to prevent overpressure in equipment or piping systems.

- When the pressure exceeds a predetermined threshold, the safety valve opens, allowing the release of pressurized fluid to the atmosphere or a designated discharge point.

- Safety valve blowdown is essential for protecting equipment, personnel, and the environment from potential hazards associated with overpressure situations.

The Parameters Chart of Blowdown Valve

| Parameter | Material |

|---|---|

| Valve Body | Carbon Steel, Stainless Steel, Cast Iron, Brass, Bronze, Alloy Steel, etc. |

| Valve Seat | Stainless Steel, Brass, Bronze, PTFE (Polytetrafluoroethylene), EPDM (Ethylene Propylene Diene Monomer), Viton, etc. |

| Valve Disc | Stainless Steel, Brass, Bronze, Alloy Steel, PTFE, EPDM, etc. |

| Valve Stem | Stainless Steel, Brass, Alloy Steel, Monel, Inconel, Hastelloy, etc. |

| Valve Actuator | Manual (Carbon Steel, Stainless Steel), Electric (Aluminum, Stainless Steel), Pneumatic (Aluminum, Stainless Steel), Hydraulic (Steel, Stainless Steel) |

| Gaskets | Graphite, PTFE, Spiral Wound, Ring Joint, etc. |

| Bolts and Nuts | Stainless Steel, Carbon Steel, Alloy Steel, Brass, etc. |

| Springs (for safety valves) | Stainless Steel, Inconel, Hastelloy, Monel, etc. |

| Seat Ring | Stainless Steel, Brass, Bronze, Alloy Steel, PTFE, etc. |

| Bonnet | Carbon Steel, Stainless Steel, Cast Iron, Brass, Bronze, Alloy Steel, etc. |